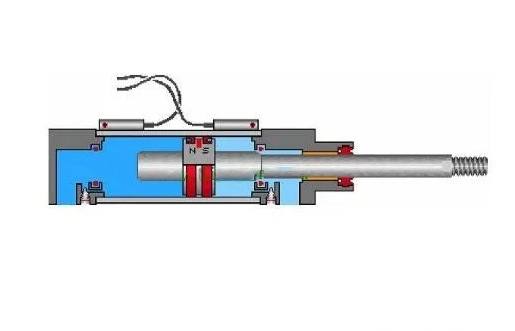

Generally, Cylinder The principle of magnetic induction switch is like this, that is, a magnetic ring is installed inside the cylinder. When the cylinder is in place, the magnetic ring supplies the magnetic induction switch. signal, thereby turning on the magnetic induction switch.

Cylinder with magnetic ring and magnetic induction switch

When the cylinder magnetic induction switch fails, it means that after the cylinder is in place, the magnetic induction switch does not light up and has no output. The reasons for this are generally the following:

1. There is a problem with the wiring. The magnetic induction switch has a three-wire system and a two-wire system. Please pay attention to the wiring

2. The installation position of the cylinder magnetic induction switch is not installed at the position of the cylinder magnetic ring. If this happens, just move the position of the cylinder magnetic ring.

3. The cylinder magnetic induction switch is damaged. Replace it with a new one to eliminate the problem.

4. There is another special situation. I encountered this situation. The cylinder magnetic switch is also on. When you detect the signal, there is also an output, but occasionally the signal cannot be triggered. The phenomenon is that sometimes, the equipment suddenly stops moving while it is running. There was no call to the police. However, when you manually move the position of the magnetic induction switch from on to off, and from off to on, the device will start again (or manually extend or retract the cylinder, try it in automatic mode, this method must be supported by the program) only then). In this case, replace the cylinder magnetic induction switch. The equipment is running normally and has been running for about 4 months. I have repeatedly checked the program and compared it with identical programs and equipment. There is no cylinder magnetic induction light, but the rising edge signal in the PLC cannot be triggered (the rising edge and the falling edge are both Give a prompt signal at the moment). Finally replace thecylindermagnetic induction switch troubleshooting.

Finally, PLC programming experience is shared. Generally, cylinder magnetic induction switches are used, and everyone likes to use rising edge signals or falling edge signals. Therefore, it is recommended that when you encounter the fourth situation, you should replace the magnetic induction switch first. According to maintenance theory, when the cause of the fault cannot be determined, use the troubleshooting method, but you need to start by replacing cheap electrical components.

The magnetic induction switch has a mechanical structure inside the reed and an electronic component inside the Hall. The switch is a reed switch. The reed switch is also called a magnetron. It is a switching element controlled by magnetic field signals. It has no magnetic disconnection and can be used to detect the status of circuits or mechanical movements.

WhatsApp: +8615857777578

WhatsApp: +8615857777578