1.

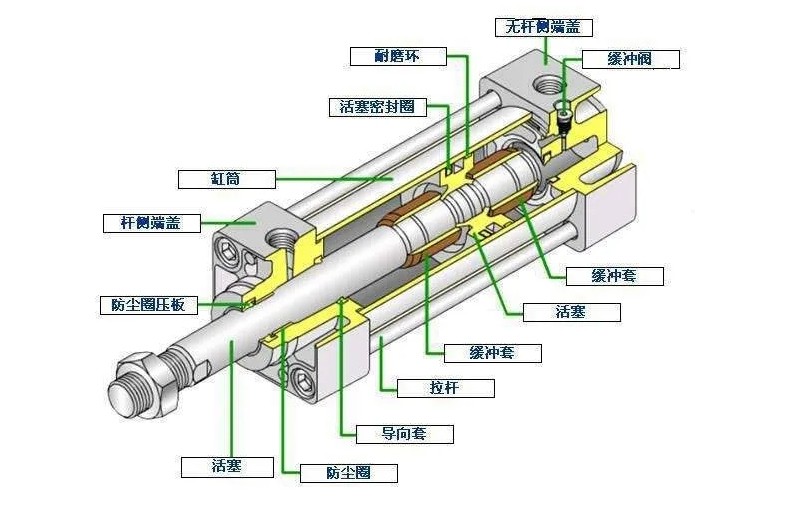

Fault caused by not resetting the cylinder in time due to throttling, exhaust throttling and throttling are commonly used to adjust the cylinder action. Although it is good, it cannot be adjusted at will. If the

cylinder, magnetic ring switch, and throttle valve are used together, it must be adjusted Pay extra attention. A Japanese production line reported that a domestic cartoning machine suddenly stopped after pushing the carton and would not move to the next step. The product was stuck here and there was no alarm on the operation screen. I began to suspect that there was a problem with the in-position detection sensor of the box pushing cylinder. After checking, its output was normal. Then I guessed that there might be a problem with the downstream mechanism. But after the investigation, I found that everything was normal. I was confused. Then I started to study the box pushing cylinder and found that it There is also a throttle valve, which I accidentally adjusted to make it reset faster. After starting the test, the problem was solved. After asking later, I found out that the throttle valve had been adjusted by the operator. The reason is that the machine is designed with safety in mind to avoid collisions between different mechanical structures at the same station. The cylinder needs to be reset in time to perform the next action. At the same time, we also remind everyone that the throttle valve must be locked after adjustment. In another case, after the shift was handed over, the machine started to run, and the machine had a door closing alarm. The machine did not go to the next step. It was found that the door closed slower than the others. Further investigation found that it was because the quick-connect joint connecting the cylinder was leaking. , and the electrician only had a throttle valve on hand, so he installed it, and this cylinder happened to have a sensor that detected it in place. The reason is the same as the previous one. I would like to remind everyone to be cautious if you insist on using a throttle valve instead of a straight-through joint. Fortunately, this device alarmed the foreigner accordingly, which saved some time.

2.

A shutdown alarm caused by the detachment of the cylinder magnetic ring switch, the automatic cartoning machine shutdown alarm is waiting for processing on a day, and it occurs. After the box pushing cylinder pushed the product out of the transfer table and the transfer table was reset, I began to suspect that there was a problem with the box pushing cylinder and its magnetic ring switch. After troubleshooting, everything was normal. Then I looked at the bottom of the transfer table. It was also controlled by the cylinder and had a Magnetic ring switch, but the magnetic ring switch fell off when the machine vibrated. After re-fixing it, the fault was eliminated. In fact, false signals caused by the failure of the magnetic ring switch can also cause such failures. Specifically, when the cylinder is reset, the magnetic ring switch indicator light is on, but there is no actual output signal.

3.

Shutdown failure caused by internal leakage of the cylinder. One day, the filling machine stopped for no reason, but there was no alarm message on the operation screen. It also happened during the cylinder push-out and reset process. I thought this was the same fault I had encountered before, so I went to check the throttle valve and magnetic ring switch with confidence. , I looked at it and found nothing abnormal, but I was confused. After careful observation, I found that the cylinder was reset a little slower than before. This is also the experience of observing the machine for a long time. Since the throttle valve and sensor are all fine, is it possible? It was a problem with the cylinder, so I replaced it with a new one

CylinderThe fault was solved. Later, in-depth investigation revealed that the cylinder was leaking! Internal leakage causes slow reset action. In fact, the internal leakage can be directly determined by observing whether the solenoid valve muffler is leaking before it is disassembled!

WhatsApp: +8615857777578

WhatsApp: +8615857777578