Input a positive pulse signal to the coil in the solenoid valve body through a wire. The working magnetic flux generated by the coil causes the moving core to attract and open the valve. When the forward pulse signal input is stopped, the moving core is released, and the moving core returns to the initial state under the action of the spring force. The valve is closed. There is also a self-maintaining type, which can be maintained even after the forward pulse input is stopped or the power is turned off. An input is required. A negative pulse signal can be reset.

The working principle is to use the pulse of electrical appliances to convert into mechanical pulsation, so that the powerful energy of the pulsating gas is turned into momentum, which is released in a short time to generate huge impulse, and is controlled by PLC. The pulse interval should be determined according to the rated gas pressure recovery time l.

Pulse solenoid valve Also known as diaphragm valve, it is the compressed air "switch" of the pulse bag dust collector dust cleaning and injection system. It is controlled by the output signal of the pulse injection controller , blowing and cleaning the filter bags row by row (chamber) to keep the resistance of the dust collector within the set range to ensure the processing capacity and dust collection efficiency of the dust collector.

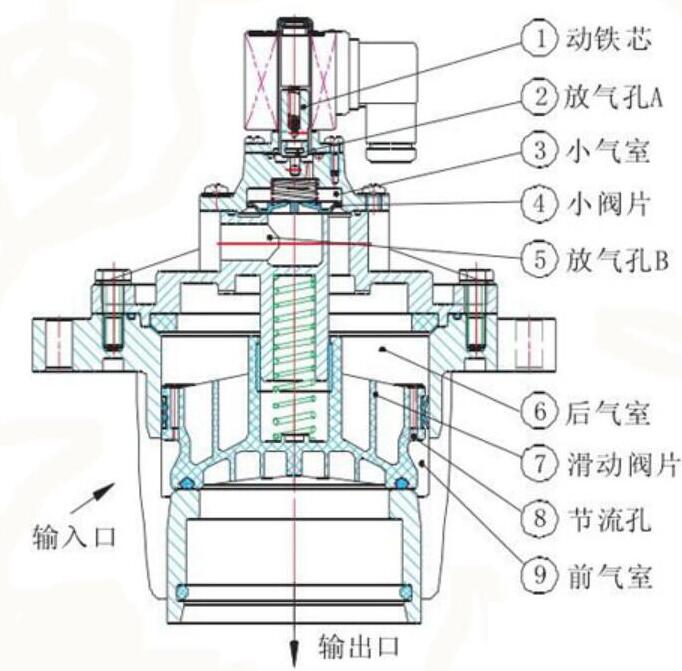

Illustration of dynamic principle of pulse solenoid valve

First of all, there is a closed cavity in the pulse solenoid valve. There are through holes at different positions. Each hole leads to a different oil pipe. There is a valve in the middle of the cavity and two pieces on both sides. The electromagnet, whichever side of the magnet coil is energized will be attracted to that side of the valve body, and control the movement of the valve body to block or leak different oil drain holes. Through the above explanation of the definition and working principle of the pulse solenoid valve , everyone should have an in-depth understanding of the pulse solenoid valve. The pulse solenoid valve is the compressed air "switch" of the dust cleaning and blowing system of the pulse bag dust collector. I hope everyone can learn the working principle of the pulse solenoid valve.

The structure of the pulse solenoid valveAs shown in the figure below, it mainly consists of pulse coil, valve core, permanent magnet, stroke It is composed of spring, valve disc and valve body.

Generally installed in the main oil circuit or shock absorber back pressure oil circuit, at the moment when the transmission automatically upshifts and downshifts or when the lock-up clutch is locked and unlocked The oil pressure is reduced at the beginning of the action to reduce the impact of shifting and locking and unlocking, making the vehicle run more balanced. Its function is to control the amount of oil pressure in the oil circuit.

Use range of pulse solenoid valve

Electromagnetic is the switch that controls the compressed air in the dust cleaning system of the bag dust collector. It is controlled by the output signal of the pulse controller and blows and cleans the filter bags in sequence, so that the dust collector The resistance is within the set range to ensure the dust removal efficiency of the dust collector;the working principle of the right-angle pulse solenoid valve is 90 degrees between the inlet and outlet, which is suitable for the installation and connection of the air reservoir and the dust collector blow pipe. The air flow is smooth and can Provides pulsed airflow that meets requirements. Products for papermaking, woodworking, dye plants, dust collectors, petrochemicals and other equipment supporting and automatic control in related industries are the first choice for bag dust removal and soot blowing systems.

WhatsApp: +8615857777578

WhatsApp: +8615857777578