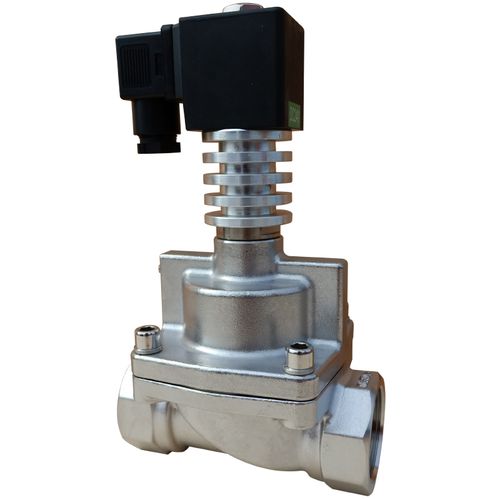

What is high temperature Steam solenoid valve?

High temperature steam Solenoid valves are suitable for actuators that use steam as the heat medium for automatic temperature control. It can perform two-position automatic control and remote control on the boiler steam pipelines of steam heaters, radiators, dryers and other steam equipment as well as temperature automatic controllers, steam setting machines, steam engines, steam resurgence machines and other complete sets of equipment. Solenoid valve is used in dyeing, textiles, printing and dyeing, food, cement products , petrochemical, metallurgy and other departments of automatic control system.

High temperature steam solenoid valve structure and working principle

The steam solenoid valve is composed of a auxiliary valve and a main valve It is a pilot-operated secondary open solenoid valve composed of two major parts. It relies on the opening and closing of the auxiliary valve to control the on and off of the main valve. According to the different switching states when the power is off, it can be divided into normally closed solenoid valves and normally open solenoid valves. Normally closed solenoid valve, when the segment point is in the normal position, the auxiliary valve port is closed, and the main valve is open circuit. When the electrical signal enters the pilot valve coil, the movable iron core is attracted by the electromagnetic force to open the auxiliary valve port, and the main valve cup is The pressure guide disappears, and the medium pressure pushes up the main valve cup. When the main valve is opened, the working medium can flow.

But when the electrical signal disappears, the movable iron core resets, sealing the auxiliary valve port, and the working medium enters the valve through the balancing hole. When the pressure tends to be balanced, the main valve spring, the valve cup's own weight and the medium pressure cause the valve cup to move downward. Move, tightly seal the main valve port, and the valve is in a closed state. Normally open solenoid valve, when the power is cut off and in the normal position, has spring action, the auxiliary valve port opens, and the main valve circulates. When the electrical signal enters the auxiliary valve coil, the movable iron core is sucked down by the electromagnetic force. When the pressure tends to be balanced, the main valve spring, the self-weight of the valve cup and the medium pressure make the valve cup move downward, sealing the valve port tightly. is closed. When the main valve is powered off, the electromagnetic force disappears, the auxiliary valve opens, the pressure in the main valve cup quickly disappears, the medium pressure holds the main valve cup up, opens the main valve port, the medium flows, and the valve is open.

Features of high temperature steam solenoid valve

1. Heat resistance: Special high-temperature resistant electrical materials and sealing materials are used for the electromagnetic part and sealing part, and various heat insulation measures are applied.

2. Wear resistance: Reasonable material selection, valve cup and guide set cleverly utilize the lubrication effect of fluid to reduce wear.

3. Condensation resistance: The condensation water in the steam pipeline will affect size: 16px;color: rgb(0, 32, 96);">Solenoid valve is an important factor in the operation. This valve is not affected by condensation water.

The above isWhat is a high temperature steam solenoid valve? High-temperature steam solenoid valve structural working principle Content introduction. If you want to know more related information, please log in to Sunway Pneumatic www.diancifa.cc to view.

WhatsApp: +8615857777578

WhatsApp: +8615857777578