1. How to calculate the force of the clamping cylinder

Finger cylinder is also called gripper cylinder, pneumatic finger, and pneumatic claw.

The working principle of the finger cylinder: The working principle of the fingercylinder is through two The piston moves, and each piston is connected to the Qigong fingers by a roller and a hyperbolic Bing, forming a special driving unit. To achieve Qigong, the fingers always move axially and concentrically, and each finger cannot move independently. If the finger is moved in the opposite direction, the previously pressurized piston is in a vented state, while the other piston is pressurized.

Methods and precautions for selecting the size of the gripper cylinder (claw)

1. When installing the air claw and accessories, the thread tightening torque should be within the allowable range. When installing accessories on your fingers, do not put any resistance on your fingers

2. The clamping point distance L and overhang H should be within the allowable range specified by the air gripper to prevent the fingers from bearing excessive torque and reducing the service life.

3. When the air claw clamps the workpiece, considering the size error of the workpiece and the presence of tape in the magnetic switch, the selected opening and closing stroke should have a certain capacity.

Parallel jaw cylinder clamping force characteristics:

The clamping jaws are in surface contact when clamped, and there is an opening distance when released. This opening distance varies according to different structural designs. It is generally in the range of 4mm-20mm, which is called The small opening distance and the large opening distance range are 20mm-100mm. The opening distance of the air claw when the clamping jaw is released. If the clamping distance is moved by a certain clamping distance during clamping, the two are subtracted and 1mm-3mm is reserved.

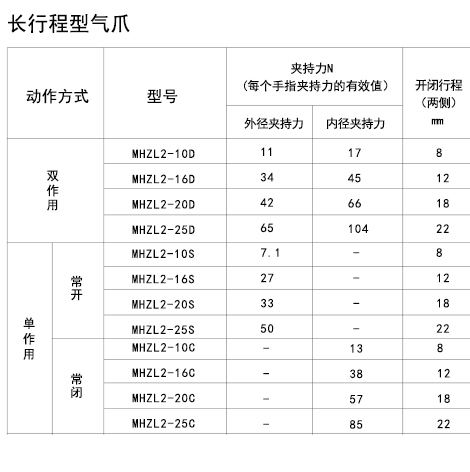

When selecting the clamping jaw cylinder, different models have different clamping forces.

2. What do o and s stand for on the clamping cylinder

Parallel clamping cylinders o and s respectively represent cylinders with different installation forms

O stands for parallel installation

S stands for three-dimensional installation

The function of the cylinder is to guide the piston to perform linear reciprocating motion in the cylinder. Air in the enginecylinderThermal energy is converted into mechanical energy through expansion;the gas is compressed by the piston in the compressor cylinder to increase the pressure.

The above isClamp cylinder How is the force calculated? What do o and s stand for on the clamping cylinder?Content introduction, if you want to know more related information, please log in to Sunway PneumaticView at www.diancifa.cc.

WhatsApp: +8615857777578

WhatsApp: +8615857777578