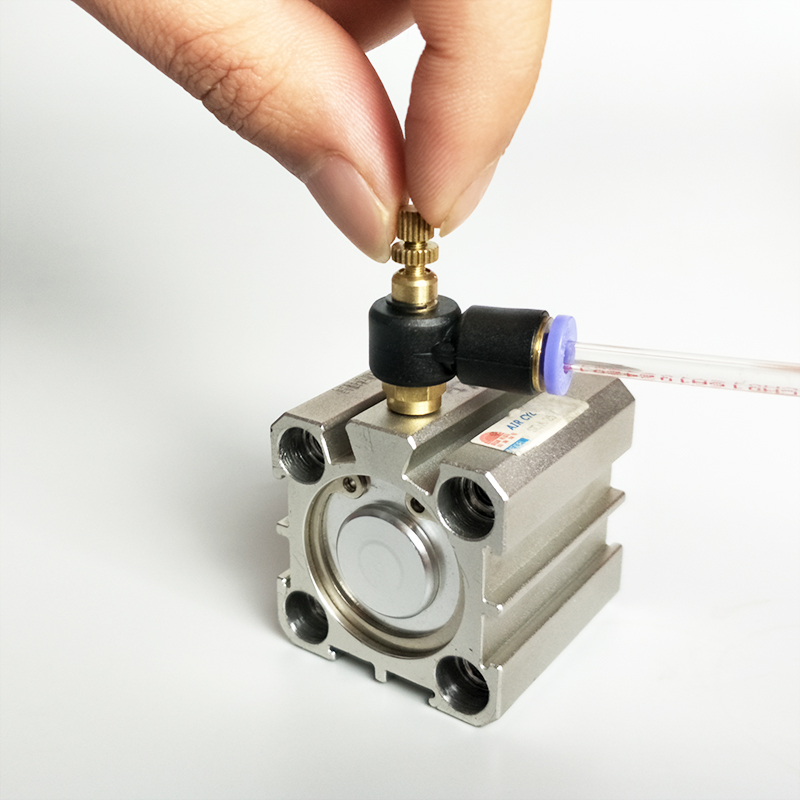

How to adjust the speed of the cylinder regulating valve, how to adjust the size of the cylinder regulating valve

Generally, pneumatic speed control valves (one upper and lower) are installed on the pneumatic cylinder. Now take the end of the cylinder with the piston rod as the top, and the end without the piston rod as the bottom. Then, if you want the cylinder to rise slower, turn down the speed control valve for exhaust air at the top (do not adjust the bottom);if you want the cylinder to descend slowly, turn down the speed control valve for the exhaust air at the bottom (do not adjust the top);On the contrary, if you want it to rise or fall quickly, turn it up. Try not to adjust it up and down at the same time. Adjust it a little and try it out, then adjust it a little more, and it will be adjusted to the ideal speed in no time.

If there is no speed regulating valve (one-way throttle valve) installed on the pneumatic cylinder, then buy two and install them, and just adjust them as described.

1. Cylinder speed control method:

1. The speed of the cylinder can be achieved by adjusting the flow rate of the intake air, such as regulating valves, throttle valves, etc.

2. If different speeds are required, multiple air circuits can be used;the combined output of the control of multiple air circuits can be achievedMultiple cylinder speeds.

2. The throttle valve is used on the cylinder:

The main function is to adjust the speed. Since there are two, one must be to adjust the feed speed and the other to adjust the return speed. Oneone is to adjust the feed speed, which is the delivery speed. The other is to adjust the speed of cylinder return.

A cylindrical metal part that guides the piston to perform linear reciprocating motion in the cylinder. The working medium converts thermal energy into mechanical energy through expansion in the engine cylinder. The gas receives piston contraction in the compressor cylinder and increases the force. The turbine rotates the piston type generator.Thermal energy is converted into mechanical energy;the gas is compressed by the piston in the compressor cylinder to increase the pressure. The casings of turbines, rotating piston enginesmotor, etc. are usually also called "cylinders". Application fields of cylinders: printing (tension control), semiconductor (spot welding machine, chip grindinggrinding), automation control, robots, etc.

Determine the push and pull forces on the piston rod according to the force required for the work. Therefore, when selecting the cylinder, the cylinder's output should have a slight margin. If the bore diameter is selected to be small, the output force will be insufficient and the cylinder will not work properly;but if the bore diameter is too large, it will not only make the equipmentheavy and costly, but also increase the air consumption. , causing energy waste. When designing the clamp, force-increasing mechanisms should be used as much as possible toreduceCylinder size.

WhatsApp: +8615857777578

WhatsApp: +8615857777578