What is the use of micro cylinders?

Micro cylinders are pneumatic tools that use the power of compressed air to move objects. Their main feature is their small size compared to other cylinder varieties. All cylinders are designed to lift or move objects. They can be used alone or in combination with other devices. Micro cylinders are characterized by their small size compared to other cylinders.

Micro cylinders can be as small as 2.5mm in diameter;Micro cylinderThe compactness allows it to perform very small tasks. This quality is very helpful for mass production of very small products, especially in the electronic component manufacturing industry. Other industries include automotive manufacturing, construction, food processing, packaging, metal processing, etc.

my country's industrial upgrading, transformation of industrial structure, and industrial automation are accelerating. The localization of the equipment industry urgently requires a large number of new pneumatic components and related technologies.

Micro cylinder model specifications

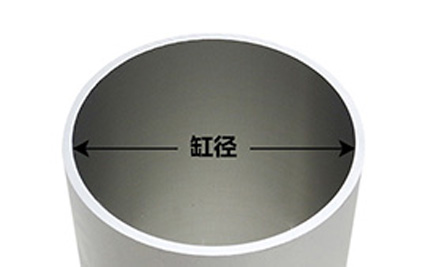

The bore diameters of micro cylinders are: 6mm, 10mm, 12mm, 16mm, 20mm, 25mm, 32mm, 40mm.

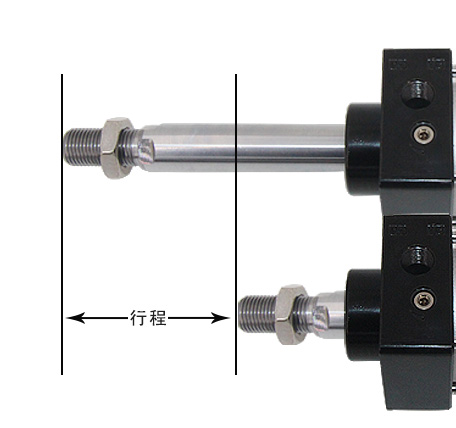

Micro cylinder stroke range takes MI micro cylinder as an example: 10mm, 20mm, 30mm, 40mm, 50mm, 75mm, 100mm.

How does the micro cylinder work?

All cylinders are equipped with a pressure-resistant metal housing, a compressed air inlet and a piston. When compressed air is forced into the housing, it displaces the piston. All loads connected to the piston will move with the piston. All cylinders have these things in common, but from there their construction varies greatly. Micro cylinders are designed to exert large forces in the smallest possible space. A medium cylinder may be considered small compared to a very large cylinder, but it may also be considered large compared to a very small cylinder. There is no universally accepted standard for larger or smaller cylinder sizes. Dimensions such as rod diameter and stroke length affect performance and may vary among cylinders of the same nominal bore from different manufacturers.

Cylinders that meet the ISO 6432 standard will meet the critical dimensions, but not all manufacturers produce cylinders that meet the standard. Because micro cylinders are so small, they can be difficult to repair, which may require replacement if the cylinder fails. In this case, installing an ISO 6432 compliant cylinder ensures that a suitable replacement is easily found.

Features and advantages of micro cylinder

There are many types of miniature cylinder back covers to choose from, and the cylinder is easy to install;the adjustable buffer type and end cover plus anti-collision buffer type buffer cylinder can well reduce the The reverse rotation impact of the cylinder has stable buffering;the end cover and the cylinder block are connected through a riveted roller package, which ensures reliable fastening. There are various cylinder specifications and models, and you can choose the model according to your needs. There are many kinds of installation accessories, and you can choose the installation method. CylinderSmall size, suitable for various small installation spaces.

1. Performance and energy saving: The micro cylinder is small in size, lightweight in quality, and the product is energy-saving and environmentally friendly.

2. Stable operation: maintain high-speed operation, high-frequency back and forth, and high-precision repeatability.

3. Complete models: Micro cylinder products are diversified and cost-effective.

4. Quality assurance: Micro cylinders have higher guarantee and reliability.

WhatsApp: +8615857777578

WhatsApp: +8615857777578