Since the cylinder can use the thrust of air pressure to generate a certain amount of inertia when it is running, this will cause the piston to not stop immediately when it moves back and forth. Therefore, It often hits the end caps at both ends of the cylinder. In order to avoid this situation from happening, a gas buffer device must be configured, that is to say, its main function is to protect the end cover and prevent the end cover from being hit by the piston.

AdjustableBuffer cylinder has a buffer valve. By adjusting the opening of the buffer valve degree, which can change the buffering capacity. The buffer stroke should not be too long: because the buffer seal ring has a throttling effect, the piston action response is slow.

How to adjust the buffering of the buffer cylinder

When the cylinder movement speed is high, an adjustable buffer cylinder must be selected. Since there is no accurate method for calculating the buffering effect, it needs to be adjusted according to the actual operating conditions;the movement speed is high and the impact energy is large, so the opening of the buffering throttle valve must be adjusted to obtain a better buffering effect.

Non-adjustable buffer cylinder: It has a constant orifice to form a back pressure and play a buffering role. Enlarging the constant orifice can increase the movement speed of the cylinder.

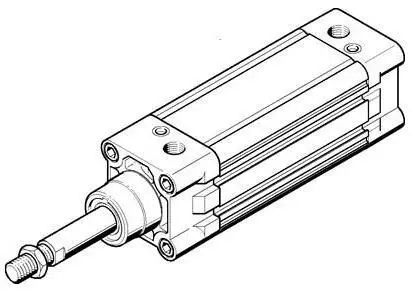

The buffer device generally consists of a buffer valve, a buffer plunger and a buffer seal ring. For example, when the piston moves to the left, the left buffer plunger contacts the left buffer sealing ring, and a closed air chamber (called a buffer chamber) is formed on the left side of the piston. The gas in the buffer chamber is exhausted outward according to the opening of the buffer valve. The piston continues to move left. The gas is adiabatically compressed and the pressure rises. The pressure produces a reaction force on the piston, which slows down and stops the piston to avoid collision. When the cylinder stroke approaches the end, due to the function of the buffer device, the high-speed moving piston can be prevented from hitting the cylinder head.

Buffer cylinder inlet pressure adjustment

It also depends on your cylinder pressure. When I originally made it, I always adjusted it to 5 atmospheres. (Of course it can be larger, but there will be other problems if it is larger). With a diameter of 32mm, you can calculate the area of the piston. Effective pressure is found by subtracting one atmosphere (air pressure) from 5 atmospheres. The effective pressure is multiplied by the area force. Of course, if you want to calculate accurately. Also consider the area of the cylinder rod. In this way, the force when the cylinder extends and retracts is different. The difference is the product of effective pressure and cylinder rod cross-sectional area. But this product is small.

Usually the cylinder selection manual provides thrust calculation formulas for different types of cylinders. And provides reference thrust for different diameters under different pressures. That should prevail.

How to repair the buffer cylinder

There may be two reasons for the failure of the upper and lower buffers of the cylinder:

One: The buffer gasket inside the cylinder has been worn for a long time, has failed, and cannot have a buffering effect;

Two: YesCylinder The buffer screws used to adjust the buffer on the upper and lower end covers are leaking or not tightened.

You can check based on the above two reasons. If it is the first problem, you can replace the buffer gasket in time;if it is the second problem, you can replace the buffer screw or tighten the buffer screw.

WhatsApp: +8615857777578

WhatsApp: +8615857777578