As we all know, the piston movement speed of a standard cylinder is generally in the range of 50~500mm/s. However, in many practical applications, the cylinder speed needs to be increased, such as high-speed transportation Devices, CNC equipment door opening and closing actions, high-speed Z-axis of robots, etc., as shown in the figure below. These applications often place high requirements on cylinder speed. For example, the high-speed Z axis requires the cylinder speed to reach 3m/s. High-speed handling devices with lower speed requirements also require the cylinder speed to reach 1000mm/s.

If the speed of the standard cylinder is higher than 500mm/s, the friction and heat generation of the cylinder seal ring will intensify, accelerate the wear of the seal ring, cause air leakage, shorten the life of the cylinder, and increase the temperature of the cylinder. The impact force at the end of the large stroke affects the mechanical life. In order for the cylinder to work at a higher speed, it is necessary to lengthen the length of the cylinder barrel, improve the machining accuracy of the cylinder barrel, improve the material of the sealing ring to reduce friction, and improve the buffering performance, etc. SMC has developed a specializedhigh-speed cylinderThe RHC series adopts a special structure with a long buffer stroke and a large air inlet diameter, which can ensure that the piston reaches a maximum movement speed of 3m/s and can decelerate smoothly. The biggest feature of the high-speed cylinder is its buffer mechanism. Here is a brief introduction to this.

What is SMC high-speed cylinder?

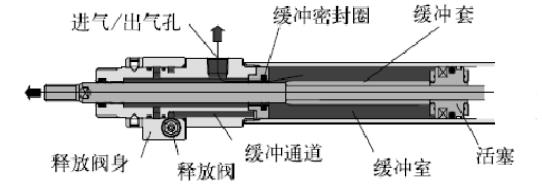

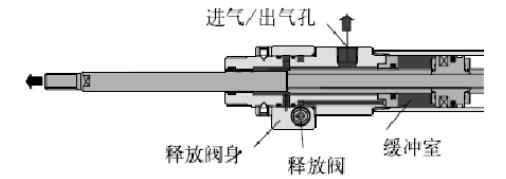

1. Before buffering starts, air enters and exhausts through the larger space between the buffer seal ring and the piston rod.

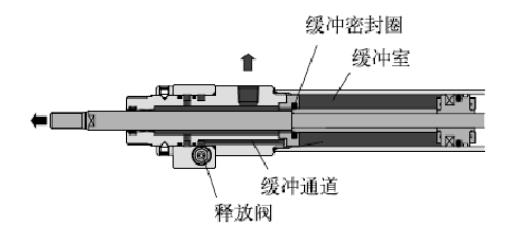

2. When the buffer sleeve contacts the buffer sealing ring, a buffer chamber is formed, and the compressed air in the cylinder can only be discharged through the buffer channel in the rod cover.

3. The air passes through the release valve (overflow valve) in the rod cover to control the speed of exhaust to obtain a smooth buffering effect.

4. When the reversing valve reverses, the piston begins to run in the opposite direction. The air passes through the buffer sealing ring and starts to push the piston away like a one-way valve.

The above process circulates and reciprocates.

District between high-speed cylinder and ordinary cylinderThe differences are as follows:

1. High-speed cylinder, the speed can reach 3 meters/second, while ordinary cylinder can only reach 0.6 meters/second.

2. The sealing structure and buffering structure of the two types are different.

3. High-speed cylinder Some of the pistons in the cylinder have magnetic rings, and some do not. This is based on need. For a cylinder with a magnetic ring, a magnetic switch can be installed outside the cylinder. When the cylinder operates, at a certain position, an electrical signal can be fed back to the PLC for control through magnetic induction (because the installation position of the magnetic switch can be changed, it can be freely ControlCylinder< /strong>itinerary).

WhatsApp: +8615857777578

WhatsApp: +8615857777578