In many occasions in industrial production, cylinder is used as a mechanical device or automatic line The actuator has been widely used. However, since the compressed air as the working medium of the cylinder is compressible, it is not easy to require the cylinder piston to stop accurately at any position during the working stroke. There is a locking cylinder abroad that can solve this problem. In a factory in Shandong, I saw that the crankshaft quenching equipment imported from abroad used a locking cylinder. According to the characteristics and functions of the locking cylinder, the structure and working principle of the locking cylinder are sorted out.

Structure of locking cylinder

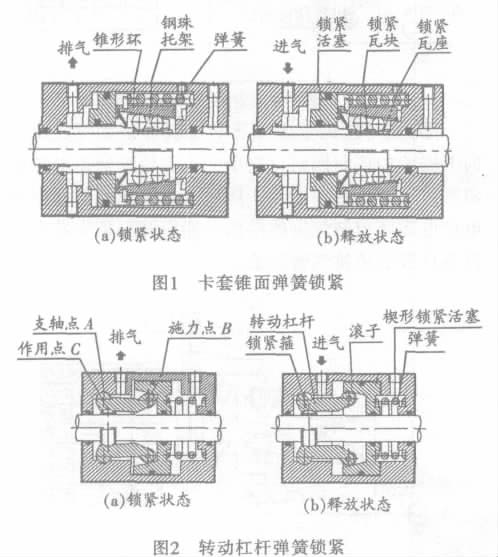

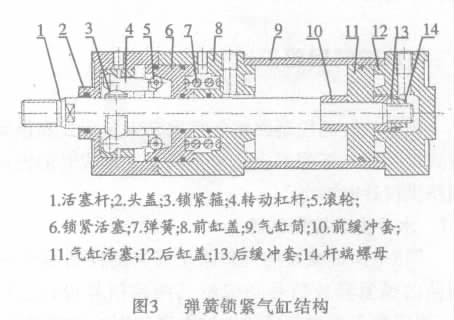

The main difference between the locking cylinder and other types of cylinders is that a locking device is attached to one end of the front cylinder head of the cylinder, and its structure has a ferrule tapered surface (see Figure 1 ), rotating lever (see Figure 2) and other forms.

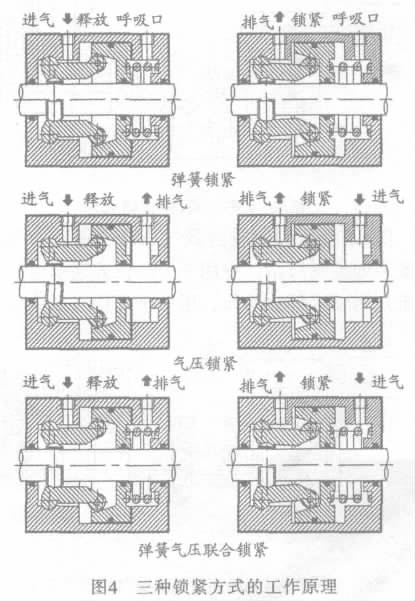

According to the locking methods, there are three types: spring locking, air pressure locking and spring and air pressure combined locking. Figure 3 shows the structural diagram of the spring locking cylinder. The locking device has two working states, namely the release state and the locking state. The following uses the rotating lever locking device as an example to introduce the working principles of the three locking methods.

Working principle of locking cylinder

Compared with diagram 4, input compressed air into the air control port to push the locking piston to move to the right against the spring force, so that the locking hoop is in a released state and the cylinder piston rod can move freely. When the air control port is rapidly exhausted, the spring force causes the locking piston to move quickly to the left. The cone surface of the locking piston forces the lever arm to rotate around the fulcrum, and then quickly tightens the piston rod through the locking hoop to stop it at a certain position. ;If no spring is used, compressed air is input from the breathing port and the air control port is exhausted to achieve the braking effect, which is air pressure locking;while the spring is locked while compressed air is input to the breathing port and the air control port is exhausted, the lock is The tightening force is greatly increased, which becomes spring and air pressure combined locking. It can be seen from the above working principle that this special cylinder can automatically and reliably maintain the locking force in the event of unexpected failure. At the same time, under the conditions of alternating load, pipeline air pressure pulsation, and pneumatic system leakage, the locking device can still accurately position and lock the piston rod for a long time. Therefore, lock thecylinderIt is gradually being used in object lifting, automatic multi-point welding, accurate automatic feeding, and workplaces where the schedule needs to be frequently changed.

WhatsApp: +8615857777578

WhatsApp: +8615857777578