As the name suggests, it is the angle at which the angle can be rotated. The general rotation range is between 0-90°. Its stroke is composed of two parts: the rotation stroke and the clamping stroke, and is used The clamping action must occur during the clamping stroke. Usage method: Corner cylinder< /a>Fixed on the workbench, equipped with hydraulic pump, filter, pressure reducing valve, reversing valve, lubricator, solenoid valve, relief valve, pipelines and connector accessories, etc., connect the pipelines Just go to the corner. Pipe fittings are selected according to actual needs.

How to distinguish between angle cylinder and rotating cylinder:

The rotary cylinders used on the market achieve planar rotary motion, not to mention the up and down motion of the output shaft.

The angle cylinder can realize the up and down movement of the output shaft. Its working principle is to use air pressure to drive the piston to rotate, and then complete the clamping stroke after rotating to a certain angle - that is, pressing down in a straight line. sports.

Working principle of the corner cylinder

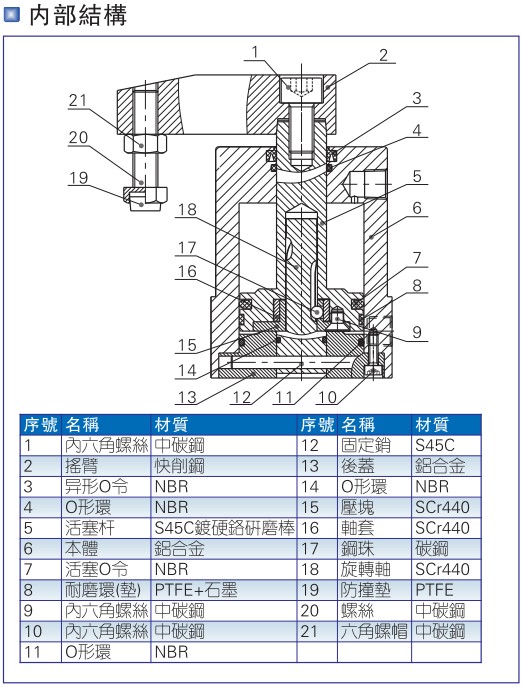

During the working process of the angle cylinder, the piston first completes the rotation stroke - the pressure arm presses down and rotates to the specified position and angle of the design, and then completes the clamping stroke - that is, straight down Press and clamp the workpiece. Before clamping the workpiece, the pressing arm leaves the workpiece. After the workpiece is installed, the pressure arm is controlled to rotate above the workpiece by reversing the direction, and then moves vertically downward to compress the workpiece;when the workpiece is released, the pressure arm automatically returns to the original position along the pressing route to let go of the workpiece. The operator can remove the workpiece smoothly and conveniently.

The angle cylinder series is divided according to the power source: it can be divided into pneumatic type and hydraulic type;

According to the installation method: it can be divided into upper flange seat type, lower flange seat type, and external thread installation method;

According to pipeline connection: it can be divided into oil manifold type and external pipeline type. When choosing, in addition to considering the power source, installation method, and pipeline connection method, the user mainly refers to the required clamping force and support force, and selects the size according to the clamping force and support force marked on each type of angle cylinder. Differentcylinder.

WhatsApp: +8615857777578

WhatsApp: +8615857777578