This kindThe characteristics of the cylinder are: 1) Compared with ordinary cylinders, the installation position can be reduced by 1/2 under the same stroke;2) No anti-rotation mechanism is required;3) Suitable for bore diameter 10~80mm, the maximum stroke can reach 7m when the bore diameter is ≥40mm;4) High speed, the standard type can reach 0.1~0.5m/s;the high-speed type can reach 0.3~3.0m/s. Its disadvantages are: 1) Poor sealing performance and prone to external leakage. When using a three-position valve, the medium-pressure type must be selected;2) The load force is small. In order to increase the load capacity, a guide mechanism must be added.

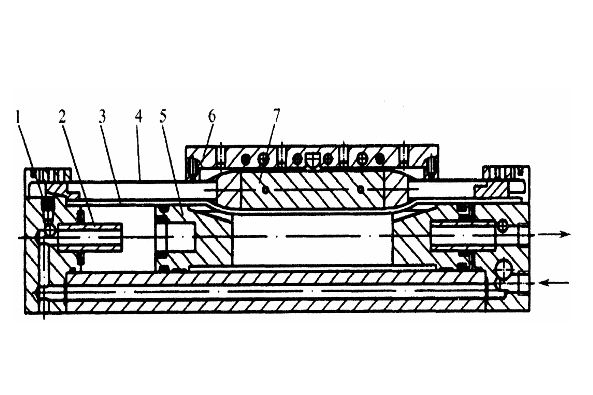

1-throttle valve 2-buffer plunger

3-Sealing belt 4-Dust-proof stainless steel belt

5-piston 6-slider 7-piston frame

WhatsApp: +8615857777578

WhatsApp: +8615857777578