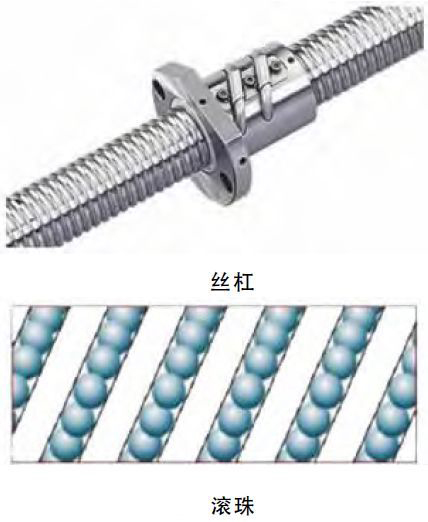

The electric cylinder mainly uses a spiral screw transmission mechanism to convert rotational motion into linear motion. Spiral screw transmission mainly includes nut screw transmission, ball screw transmission and planetary roller screw transmission. Ordinary nut and screw mechanisms are gradually being eliminated due to shortcomings such as large transmission friction resistance and low transmission efficiency. At present, ball screw transmission and planetary roller screw transmission are more commonly used.

Ball screws are currentlyElectric cylinder One of the most commonly used transmission elements, its main function is to convert rotational motion into linear motion, or convert torque into axial repetition force, while having the characteristics of high precision, reversibility and high efficiency. Since many balls perform rolling motion between the screw shaft and the screw nut of the ball screw pair, the electric cylinder using the ball screw can achieve higher motion efficiency.

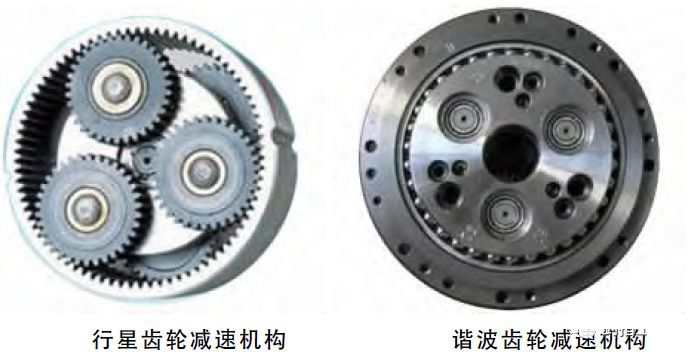

2. Reduction mechanism

The reduction mechanism of the electric cylinder can use synchronous belts, planetary gear reducers, harmonic gear reducers, etc.

The synchronous belt drive is composed of an endless belt with equally spaced tooth shapes on the inner circumferential surface and corresponding matching wheels. It combines the advantages of belt drive, chain drive and gear drive. Synchronous belt drive is mostly used on reciprocating electric cylinders. Synchronous belt transmission has the advantages of accurate transmission, constant transmission ratio, and smooth transmission. Some electric cylinders adopt a planetary gear reduction mechanism in the selection of reduction device.

Planetary gear transmission is a gear transmission that causes the axis of one or more planetary wheels to rotate around the fixed axis of the center wheel. Planetary gear transmission has the advantages of small size, light weight, and high load-bearing capacity. Harmonic gear reducer is also one of the commonly used reduction devices for electric cylinders. The so-called harmonic transmission is a general term for a device that relies on the elastic deformation of an intermediate flexible component to achieve motion and power transmission. Harmonic gear transmission has the advantages of simple structure, small size, large load-bearing capacity, large transmission ratio range, high motion accuracy, small and uniform tooth surface wear

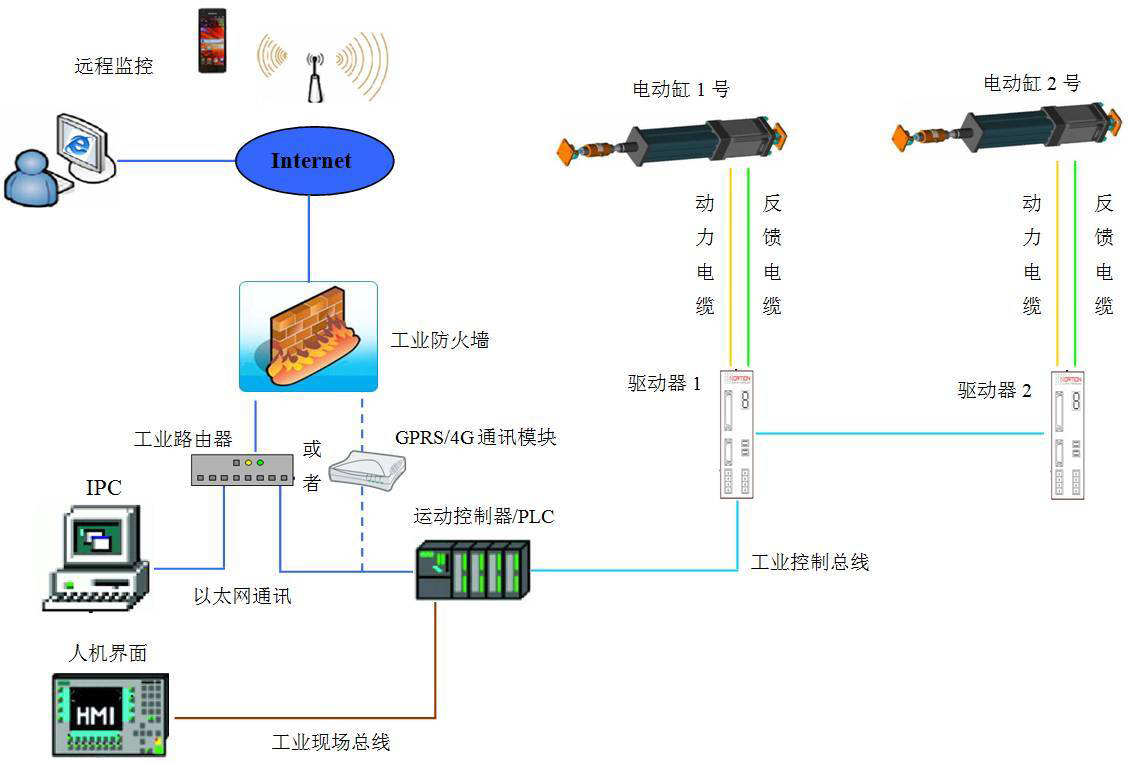

3. Control system

The core component of the servo electric cylinder is the servo motor. The electric cylinder system utilizes the closed-loop control characteristics of the servo motor. The servo motor driver itself also has various controls such as displacement, speed, and torque. mode, but in order to achieve the freedom and diversity of control strategies to optimize the quality of displacement, velocity, and acceleration curves, an open control system is established using PC, motion controller or PLC, execution and auxiliary units, and closed-loop control is used to further improve Control quality. This technology, combined with computer control technology, can achieve high-precision dynamic closed-loop control of the servo electric cylinder's push rod displacement, speed, thrust, and acceleration, providing a technical foundation for servo electric cylinder control. Utilize modern motion control technology, CNC technology and network technology to achieve programmed, networked and intelligent control.

WhatsApp: +8615857777578

WhatsApp: +8615857777578