The angle seat valve maintains the flow rate and saves space. It uses a single-acting pneumatic actuator with spring safety protection to operate the guideAngle seat valve. When in use, normally open or normally closed should be selected. Angle seat valves are widely used in frequent starts in short periods of time and have the characteristics of sensitive response and accurate action.

The angle seat valve cooperates with the solenoid valve to accurately control the flow of gas and liquid using pneumatic control. It can achieve accurate temperature control, dripping liquid and other requirements.

Applications of angle seat valves in daily life: 1. Control of gases, neutral gases, and air. 2. Control liquids, automated industrial control fluids, food-grade dairy industry, domestic water, ordinary pipeline fluid media, etc.

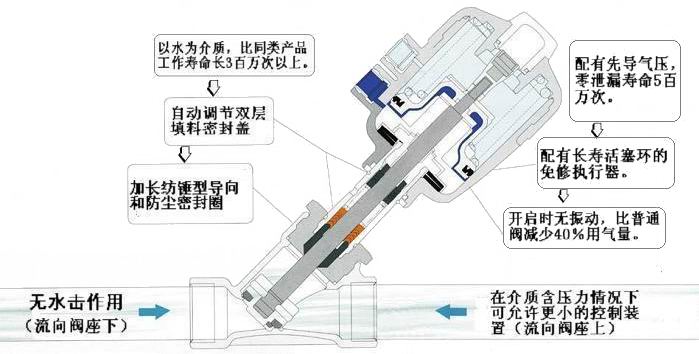

Angle seat valve features:1. With valve open or closed position display. 2. External pneumatic pilot can increase the service life and is maintenance-free. 3. There is a self-adjusting sealing gland between the overflow port and the slider, which can improve the sealing performance. 4. The angle seat structure of the valve body can achieve large flow (especially compared with ordinary stop valves), and the structure is compact and the response is fast.

Working principle of angle seat valve

Angle seat valve is opened and closed based on spring return. It can be divided into normally open type and normally closed type, single-acting and double-acting cylinders for switching.

Double-acting (the pneumatic head usually has two holes);working principle: air supply and air shut-off control its switch.

Single-acting (the pneumatic head is usually a hole);working principle: open air supply, close air supply.

The angle seat valve maintains the flow rate and can save space. It uses a single-acting pneumatic actuator with spring safety protection to operate the guided angle seat valve. You should choose normally open or normally closed when using it. The product is made of stainless steel casting and polytetrafluoroethylene and can be used for most gases and liquids. For steam and corrosive applications, it comes with a heat sink to protect the actuator. Make sureangle seat valveIt has a long life and flexible installation position. In order to facilitate the positioning of the pressure interface, the actuator housing is rotated 350 degrees to enhance flexibility, and comes with a standard display for open or closed status.

Angle seat valve installation and maintenance must comply with applicable safety regulations

1. Pipelines must be clean and pollution-free.

2. Install as needed, but with the actuator facing upwards. Pay attention to the flow direction.

3. When connecting the valve, pay attention to aligning the pipe. Only remove the actuator when the user has special requirements.

4. Before opening or repairing the angle valve, cut off the fluid and control air source and reduce the pressure in the pipeline system.

WhatsApp: +8615857777578

WhatsApp: +8615857777578