Check valve is also called one-way valve or check valve. Its function is to prevent the medium in the pipeline from flowing back. The bottom valve that shuts off water from the water pump also belongs to the check valve category. There are two types of body cover connection design forms for forged steel check valves: the first is a forged steel check valve with body cover bolted connection. For valves designed according to this connection form, the valve body and valve cover are connected with bolts, and the winding gasket The advantage of the sheet seal is that it is easy to maintain;the second type of forged steel check valve with a fully welded body cover and sealed seal. For valves designed according to this connection form, the valve body and the valve cover are connected with a screw mosquito, and the fully welded seal has the advantage of no leakage. .

< strong>One-way check valve refers to a valve that relies on the flow of the medium itself to automatically open and close the valve disc source to prevent the medium from flowing back. It is also called a check valve and a one-way valve. valve, reverse flow valve, and back pressure valve. The check valve is an automatic valve whose main function is to prevent the backflow of the medium, the reverse rotation of the pump and drive motor, and the release of the container medium. Check valves may also be used on lines supplying auxiliary systems where the pressure may rise above the system pressure. Check valves can be mainly divided into swing check valves (rotating according to the center of gravity) and lift check valves (moving along the axis).

The function of this type of check valve is to only allow the medium to flow in one direction and prevent the flow in the opposite direction. Usually this kind of valve works automatically. Under the pressure of fluid flowing in one direction, the valve disc opens;when the fluid flows in the opposite direction, the fluid pressure and the self-weight of the valve disc act on the valve seat, thereby cutting off the flow.

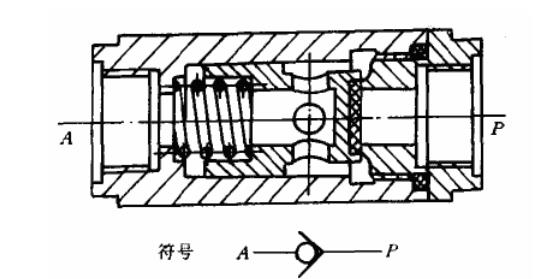

The working principle of one-way check valve

The fluid in the one-way valve can only flow along the water inlet, and the medium at the water outlet cannot flow back. It can be used in hydraulic systems to prevent reverse flow of oil flow, or in pneumatic systems to prevent reverse flow of compressed air. One-way check valves include: straight-through type and right-angle type. Straight-through check valve: installed on the pipeline with threaded connection;right-angle check valve: available in three forms: threaded connection, plate connection and flange connection.

The one-way valve is a directional control valve that allows air and other substances to flow in only one direction but not in the reverse direction. Its working principle is the same as that of a hydraulic one-way valve. Compressed air enters from the inlet, overcoming the spring force and friction to open the one-way valve port, and the equipment compressed air flows from P to A;when there is no compressed air at P port, the spring force and the residual air force at A port (cavity) act Down. The valve port is closed, blocking the air flow from A to P.

One-way check valve is used in situations where the reverse flow of air is not allowed. For example, when an air compressor inflates a gas tank, a gap is installed between the air compressor and the gas tank. The one-way valve prevents the compressed air in the tank from flowing back to the air compressor when the air compressor stops working. One-way valves are often combined with throttle valves, sequence valves, etc. to form one-way throttle valves and one-way sequence valves. Its impact on industry and other fields is of great significance. It makes up for the defects of many equipment and improves productivity and economic benefits.

WhatsApp: +8615857777578

WhatsApp: +8615857777578