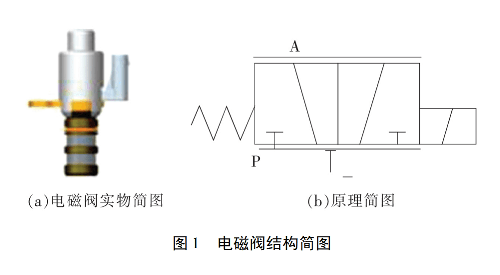

Solenoid valveThe structural diagram is shown in Figure 1. The valve has three oil ports, of which P and A are the oil supply ports, and T port is the oil return port. . As the current changes, the electromagnetic force on the armature, the displacement of the valve core and the oil pressure at the oil outlet also change. According to the corresponding relationship between the current and the valve core displacement, the current is continuously adjusted to control the valve core displacement, thereby achieving the purpose of controlling the oil pressure at the oil outlet. There are two working states. Solenoid valve When the power is turned off, the valve core is in the original position, and the A-T oil port Connected;when the power is on, the solenoid coil is energized, causing the valve core to move to the other side against the spring resistance, and cooperates with the valve sleeve to realize oil circuit switching, and the P-A oil ports are connected. In order to achieve reliable operation of the valve, the following performance tests are required.

1. Leak test

Whether there is internal leakage when the valve is working is a key indicator to measure its quality. Due to factors such as sealing and wear, leakage is inevitable, so the test indicator is that the leakage amount cannot exceed the maximum leakage value, which needs to be <0.5L/min. The specific test method is as follows:

When the valve is not open, the A-T ports are open. At this time, by supplying oil to the P port, slowly increase the pressure of the P port from the minimum value to the maximum value, and the valve core will move to the other side under the action of the pressure oil. On one side, the state of the valve changes to P-A. In this process, the flow rate leaking from P port to T port inside the valve is measured when A-T ports are connected, and then the pressure is reduced from the maximum value to the minimum value. , the valve core returns to the initial state and the A-T ports are connected. During this process, the flow rate leaking from the valve to the T port when the P-A ports are connected is measured. Since the leakage volume is very small, a high-precision gear flow sensor is needed to test the leakage volume of the valve. The measurement range is (5 ~ 1000) ml/min, and the accuracy is 0.5% FS.

2. Output flow-current signal characteristics test

Through this test, the output flow curve of the valve can be obtained as the electrical signal changes under different pressures, and the valve's output flow curve can be analyzed. Steady state characteristics.

When testing, set the starting point and ending point of the current, first stabilize the inlet oil pressure to the required value, then increase the electrical signal of the tested valve from the minimum value to the maximum value, and then return to the starting point, and draw the flow-current characteristic curve.

3. Step response time test

There are two conditions for testing the response time of the solenoid valve, namely the valve power-on response time and the power-off response time. Both are required according to the manufacturer's requirements. Less than 30ms.

(1) The initial state is power outage: At this time, the valve core is in the original state A-T is open, port A is closed, and the oil pressure at port P is stabilized to Solenoid ValveA rated current signal is detected at the moment when the solenoid coil is energized, and the time it takes for the valve core to react and cause the oil pressure at port A to rise to 90% of the oil pressure at port P is the power response time.

(2) The initial state is energized: At this time, the valve core is in the state of P-A communication, the P port stabilizes the oil pressure, causing the solenoid coil to instantly cut off power, and detects when the A port oil pressure drops to 10%. time, which is the power-off response time.

The above isSolenoid valve leakage, signal characteristics, step response time detection method Content introduction, if you want For more information, please log in to www.diancifa.cc.

WhatsApp: +8615857777578

WhatsApp: +8615857777578