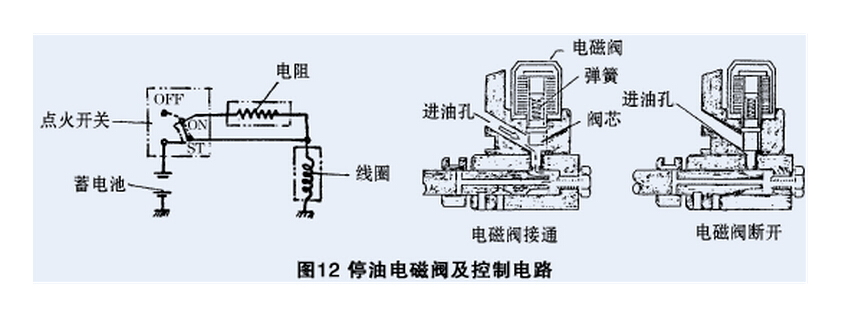

Oil cut-off solenoid Valve working principle

The speed limiting principle of the diesel engine relies on the energization and deenergization of the oil cut-off solenoid valve coil to realize fuel injection and fuel cut-off. The coil windings include a strong current traction coil (suck-pull coil) and a weak current holding coil connected in parallel. (Keeping coil), a plunger is located in the coil core and its head is supported by a return spring, and is connected in series in the traction coil circuit. When the vehicle speed reaches the speed limit, the iron core reaches the top and the suction coil is short-circuited. The position of the valve core is maintained by the holding coil. The position of the valve core is controlled and the oil volume is controlled so that the vehicle speed no longer increases. The switch of the diesel engine serves as the power switch for the holding coil, and the power from the starter serves as the working power for the traction coil.

A diesel engine oil cut-off solenoid valve, including a coil winding and a piston device. The coil winding includes a strong current traction coil and a weak current connected in parallel. To hold the coil, a piston is located in the coil core and its head is supported by a return spring. The switch of the diesel engine serves as the main switch for the traction coil and the holding coil. The piston can directly act on the control of the oil valve. The gear rod can also control the existing oil cutoff tie rod. The utility model achieves the purpose of automatic flameout by affecting the connecting rod through the movement of the piston, so that the diesel locomotive can realize automatic flameout like a gasoline locomotive.

Installation inspection of oil cut-off solenoid valve

1. Before installing the solenoid valve, carefully check the main power incoming circuit to confirm the fuse, the main switch connection is normal, and the main switch voltage output Whether it is above 24V;if there is any abnormality, be sure to check it.

2. Check the wiring of the solenoid valve. Generally, there are three wires: black, white, and red. The black wire is the common terminal, the white wire is for maintaining the weak current input, and the red wire is for the strong current input at startup. The three wires must be connected correctly. Before wiring, recheck whether the wire voltage is 24V. above.

3. Connect correctly< strong>Solenoid valve At the inlet end, test it first, turn on the car, power on the whole vehicle, close the flameout solenoid valve, and make sure that the solenoid valve has been fully closed in place. If it is not in place, it will be easy. If it is broken, hold the solenoid valve body with your hands for three to five minutes to see if it gets hot. If not, it means the installation is normal.

4. After the installation test is normal, the key is turned off, and then After installing it correctly on the engine, it is also very important to adjust the position of the tie rod. If the position of the tie rod is not adjusted properly, it will also cause the shutdown solenoid valve to not be closed in place and burn out.

5. After installation, turn on the machine to test the operation of the solenoid valve status, increase the throttle, coax for a few minutes, touch the temperature of the solenoid valve body, if it does not heat up, it means it is normal, and the solenoid has been successfully installed!

The above isWorking principle of oil cut-off solenoid valve, installation inspection of oil cut-off solenoid valve Content introduction, if you want For more information, please log in to www.diancifa.cc.

WhatsApp: +8615857777578

WhatsApp: +8615857777578