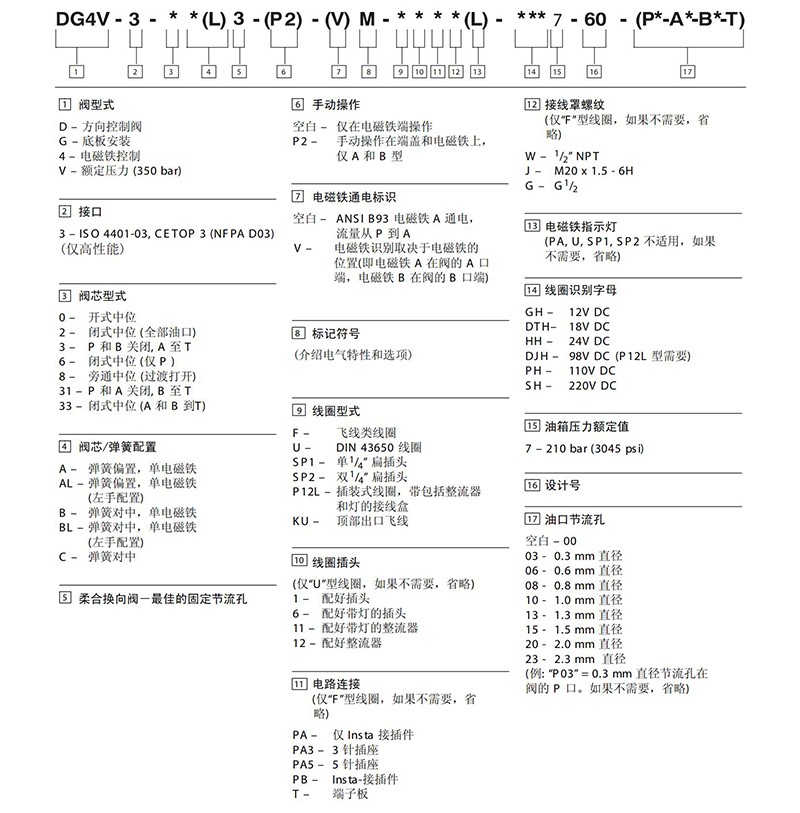

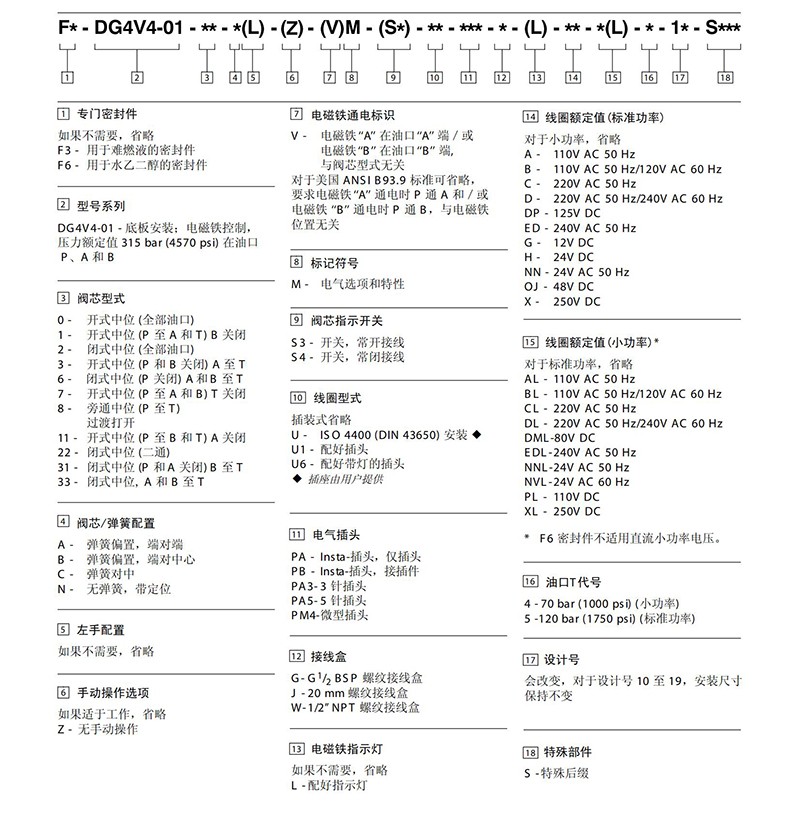

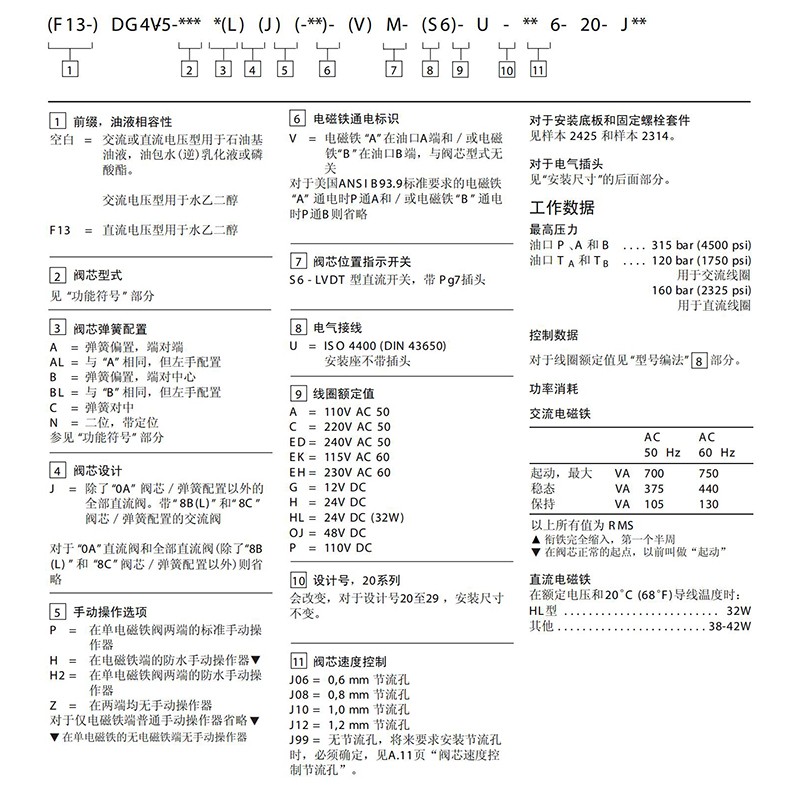

Vickers Solenoid valve model meaning

Vickers solenoid valve The role of

Vickers solenoid valves are mainly used as actuators in electro-hydraulic servo systems (see hydraulic servo systems). In the servo system, compared with electrical and pneumatic actuators, hydraulic actuators have the characteristics of good speed, large output power per unit weight, smooth transmission, and strong anti-interference ability. On the other hand, electrical components are often used in servo systems to transmit signals and correct characteristics. Therefore, modern high-performance servo systems also use electro-hydraulic methods, and servo valves are essential components of such systems.

Working principle of Vickers solenoid valve

Vickers solenoid valve and safety valve are integrated to form a pilot pressure valve. This valve is both an unloading valve and a safety valve. Sometimes it's a relief valve. During unloading, its control oil passage runs through each reversing valve, which is the same as the aforementioned unloading oil passage. When each reversing valve is in the neutral position, the control oil passage of the unloading valve (see Figure 1b and Figure 2) runs through each reversing valve and is connected to the fuel tank. During unloading, most of the oil is unloaded, the passage is short, and the pressure loss is low. When any valve is reversing, the control oil channel is cut off, and the oil from the source enters the actuator from the reversing valve, and its working pressure is controlled by the pilot valve. At this time, the system pressure is the pilot valve adjustment pressure. This unloading method, even if the number of reversing valve circuits increases, only the control oil passage increases, the unloading pressure does not increase much, and the unloading pressure is always maintained at a low level. This unloading method is mostly used for manual reversing valves, and the unloading is reliable. .

VickersSolenoid valve The main valve (also a safety valve) can be divided into three-stage concentric, two-stage concentric and sliding according to the different matching forms. Three types of valves. Among them, the slide valve structure has low working pressure and low control pressure accuracy;although the three-stage concentric structure is mature and currently widely used, compared with the two-stage concentric type, it is not as sensitive as the two-stage concentric type. When the specifications are the same and the stroke is the same, The oil flow capacity of the two-stage concentric structure is much greater than that of the three-stage concentric structure;the two-stage concentric structure has stable control pressure and good processing technology. The two-stage concentric structure has broad application prospects. Here, the two-stage concentric structure is used to discuss its structural size design method.

The pilot oil from the Vickers solenoid valve controls the movement of the main reversing valve spool, allowing the oil from the working pump to enter the boom cylinder to achieve the rise of the boom. The greater the output pressure of the proportional pilot pressure reducing valve, the greater the displacement of the main reversing valve spool, the greater the flow rate through the main reversing valve, and the faster the boom rises. When the operating handle is pulled to the extreme position, the limit electromagnet in the handle is energized, and the handle is attracted at the extreme position. The boom rises at the maximum speed. When it reaches the position defined by the upper limit switch of the boom, the operating handle limit electromagnet is powered off, the handle automatically returns to the neutral position, and the boom can be maintained at the limited position. During the raising process of the boom, if the boom needs to stay at a certain position, the operating handle needs to be returned to the neutral position.

The above isThe meaning of Vickers solenoid valve model, the function and working principle of Vickers solenoid valve Content introduction, if you want to know more relevant information, please log in to www.diancifa.cc to view the Dianwei Pneumatic.

WhatsApp: +8615857777578

WhatsApp: +8615857777578