Diaphragm type Working principle of solenoid valve

Diaphragm type solenoid valve is a pilot type solenoid valve that opens the valve twice. Its structure mainly consists of a pilot valve and a main valve. The main valve adopts a rubber sealing structure. In the normal position, the movable iron core seals the pilot valve port, the pressure in the valve cavity is balanced, and the main valve port is closed. When the coil is energized, electromagnetic force is generated to suck up the movable iron core, and the medium in the main valve cavity leaks out of the pilot valve port, resulting in a pressure difference. The diaphragm or valve cup is quickly lifted up, the main valve port opens, and the valve becomes Passage. When the coil is powered off, the magnetic field disappears, the movable iron core resets, and the pilot valve port is closed. After the pressure in the pilot valve and main valve cavity is balanced, the valve is closed again.

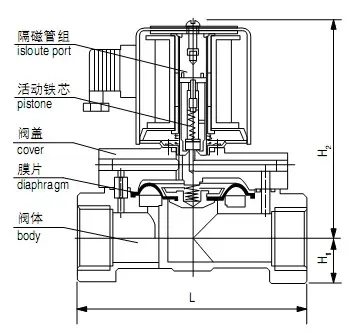

Diaphragm type solenoid valve structure

Use and maintenance of diaphragm solenoid valve

1. It is recommended that the user unit assign a dedicated person to be responsible for its use and maintenance;

2. Regular maintenance 1-2 times a year is Solenoid Valve< /span>The best way to work reliably and live longer. The following four conditions inside the solenoid valve are the reasons that hinder the normal operation of the solenoid valve and shorten its life.

1) The medium changes during use; span>

2) Rust inside the pipe;< /p>

3) The oil in the air compressor oxidizes, producing carbon particles, tar and other impurities 2.4 There are dust particles, dirt and other impurities in the pipeline;

3. After the solenoid valve is installed or put into operation again after a long period of inactivity, it must be introduced into the medium and tested for several times before it can be officially used;

4. Before maintenance, the power supply must be cut off and the medium pressure must be removed;

5. The coil assembly should not be disassembled;

6. When disassembling the solenoid valve for cleaning, you can use kerosene, trichlorethylene and other solutions, but it should be Note that the rubber part may swell, so it must be replaced;

7. When disassembling and cleaning, all parts should be restored to their original state in order and installed.

The above isWorking principle of diaphragm solenoid valve, structure of diaphragm solenoid valveContent introduction, think For more information, please log in to www.diancifa.cc.

WhatsApp: +8615857777578

WhatsApp: +8615857777578