Water solenoid valve It is suitable for water or liquid as the working medium, and can automatically control or remotely control the opening and closing of water, oil, liquid and other working medium pipelines . Since this valve adopts rubber seal, the cleanliness of the working medium is greatly reduced, and it has the characteristics of rapid opening and closing and high reliability.

Working principle of water solenoid valve

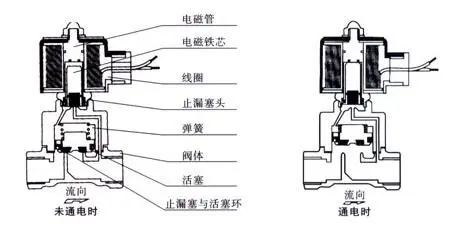

The water solenoid valve is a pilot-operated solenoid valve that opens the valve twice. Its structure mainly consists of a pilot valve and a main valve. The main valve is made of rubber. Sealed structure. In the normal position, the movable iron core seals the pilot valve port, the pressure in the valve cavity is balanced, and the main valve port is closed.

When the coil is energized, electromagnetic force is generated to suck up the movable iron core, and the medium in the main valve cavity leaks out of the pilot valve port, resulting in a pressure difference. The diaphragm or valve cup is quickly lifted up, the main valve port opens, and the valve It's a passage. When the coil is powered off, the magnetic field disappears, the movable iron core resets, and the pilot valve port is closed. After the pressure in the pilot valve and main valve cavity is balanced, the valve is closed again.

There is a closed cavity in the water solenoid valve, with through holes at different positions. Each hole leads to a different oil pipe. There is a valve in the middle of the cavity and two electromagnets on both sides. Which side of the magnet coil is energized by the valve body? Which way will it be attracted? By controlling the movement of the valve body to block or leak out different oil drain holes, and the oil inlet hole is normally open, the hydraulic oil will enter different oil drain pipes, and then through the oil pressure Push the piston of the oil cylinder, the piston drives the piston rod, and the piston rod drives the mechanical device. In this way, the mechanical movement is controlled by controlling the current of the electromagnet.

Water solenoid valve installation method steps

1. Solenoid valves are generally directional. Do not install it backwards. Usually, "→" is used on the valve body to indicate the direction of medium flow. When installing, it must be installed in the direction indicated by "→".

2. Manual cut-off valves should be added before and after the solenoid valve , and a bypass should be set up to facilitate maintenance of the solenoid valve in case of failure.

3. If the medium will cause water hammer, Then you should choose a solenoid valve with waterproof hammer function or take corresponding preventive measures.

4. Use a pressure of 0.3MPa before taking over. Pipe flushing removes metal powder, sealing material residue, rust, etc. in the pipeline. Pay attention to the cleanliness of the medium. If the medium is mixed with dirt, impurities, etc. that will hinder the normal operation of the solenoid valve, a filter valve (filter screen ≥ 60 mesh) should be installed in the pipeline.

5. The inlet side of the steam solenoid valve should be installed If there is a drain valve, the connecting pipe should be tilted.

6. The solenoid valve should not be installed in the recessed position of the pipeline. place, install it in the discharge pipe of the container, be careful not to lead it out from the bottom of the container, but should be installed slightly above the bottom of the container.

7. When taking over the pipe, please note that sealing materials cannot be used. excess.

8. Try not to let Solenoid valve is in the energized state for a long time, which can easily reduce the service life of the coil or even Burning out the coil means that normally open and normally closed solenoid valves cannot be used interchangeably.

The above isWorking principle of water solenoid valve, installation method and steps of water solenoid valve Content introduction, think For more information, please log in to www.diancifa.cc.

WhatsApp: +8615857777578

WhatsApp: +8615857777578