Why is the solenoid valve Will break

< strong>1. The coil is burned out

< span style="font-size: 16px;">If the solenoid valve operates for a long time, the coil will inevitably burn out. If the solenoid valve does not produce oil after being plugged in, the coil will be abnormal. Moreover, the internal mandrel has no suction force. In this case, the coil is burned out and needs to be replaced Solenoid valve coil.

2. Abnormal sound

< span style="font-size: 16px;">Sometimes when the solenoid valve is energized and running, AC noise will occur. The reason is that the coil nut is loose. At this time, the pilot valve should be cleaned to remove foreign matter inside, and then the nut should be tightened.

3. The solenoid valve is stuck

Usually, the gap between the solenoid valve slide sleeve and the valve core is very small, usually less than 0.008 mm. When impurities enter or there is too little lubricating oil, the solenoid valve can easily get stuck. live.

4. Air leakage

< span style="font-size: 16px;">Solenoid valves are prone to air leakage. Once air leaks, it will cause insufficient air pressure, making it difficult to open or close the forced valve.

5. The small hole of the pilot valve is blocked

When the dirt in the pipeline blocks the small hole of the pilot valve, the pilot valve will not be able to open. The solution is to disassemble the valve body first, clean the internal stains, and then reinstall it.

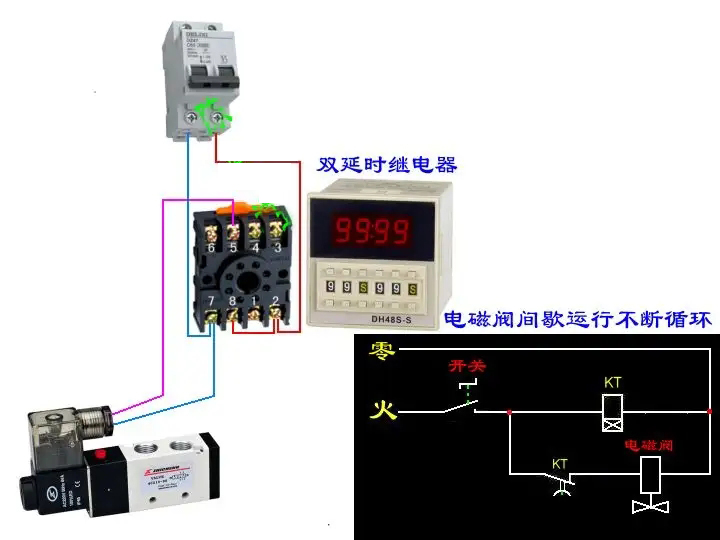

How to adjust the solenoid valve time

Generally, PLC is connected to the solenoid valve through an intermediate relay, so the PLC output delay, relay and Solenoid valveThe influence of action delay. In addition, the plsy instruction output on-off time is 1:1, and the on-off time can be flexibly set using a timer.

The above isWhy does the solenoid valve break and how to adjust the solenoid valve time Content introduction, want to know more For more related information, please log in to www.diancifa.cc to view the Shenwei Pneumatic.

WhatsApp: +8615857777578

WhatsApp: +8615857777578