The difference and connection between solenoid valves and cylinders

Answer: The solenoid valve is for control and the cylinder is for execution!

1. The cylinder is a pneumatic mechanical component, used to achieve mechanical movement or action, and is driven by compressed air.

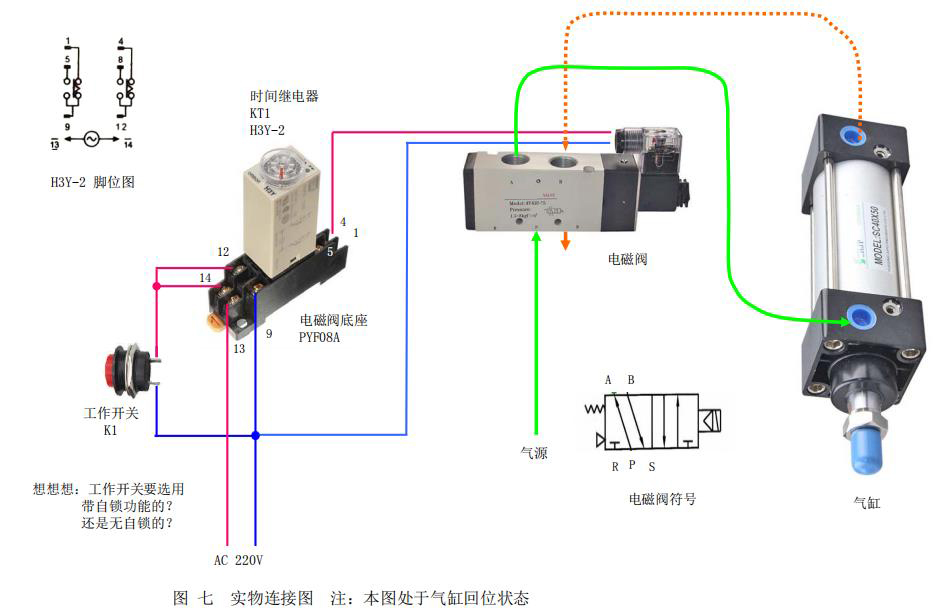

2. The solenoid valve is an electric valve that controls the air path of the cylinder. It is used to switch and control the opening and closing of the air path, and control the compressed air to the cylinder to cause the cylinder to move and action.

3. With the cylinder and Solenoid valve also requires a cylinder controller. Usually the TPC8-8TD timing program controller is used as the cylinder controller, and a table is used to set the required Function, without programming, can easily realize automatic control of cylinder equipment.

How to match and select solenoid valves and cylinders

Single-acting cylinder--3-way solenoid valve

Double-acting cylinder--4.5-way solenoid valve

Control various fluids-2.3-way solenoid valve

The switching actions of the double-acting cylinder are all driven by the air source;ventilation is on, ventilation is off, and the air is cut off to remain in place;

For single-acting switches, only the opening action is driven by the air source, while the closing action is spring-return;(more micro cylinders)

Single-action is divided into: normally open type and normally closed type.

Normally open type: (ventilation off, air off and on);

Normally closed type: (open for ventilation, closed for ventilation).

The strokes are all selected according to specific industrial and mining requirements. Single-acting valves are generally used when power and gas are cut off, and the valve is required to be opened or closed. Single-acting ones are more expensive than double-acting ones, and double-acting ones are generally used. The specifics still depend on the user's industry and mining.

Single-acting cylinder VS double-actingCylinder are compared as follows:

1. Single-acting is cheaper than double-acting and the entire gas circuit costs less.

2. Cylinder The spring recovery speed is stable and is not affected by changes in air pressure.

Disadvantages:

1. Under the same pressure and flow rate, single-acting speed is slower than double-acting.

2. Single-action has a single function than double-action. (For example, double-acting can be connected to a three-position five-way middle seal, medium voltage, etc. to achieve safety functions, but single-acting cannot achieve this function)

There is a spring in the single-acting cylinder for reset. If the stroke is too long, the spring will also be very long, resulting inCylinderThe overall length is also long, the spring is unreliable, and the thrust changes during the process Too big and unstable. Therefore, single-acting cylinders are generally short-stroke small cylinders.

The above isSolenoid valve and The differences and connections between cylinders, how to match and select solenoid valves and cylinders Content introduction, if you want to know more related information, please log in to Sunway PneumaticView at www.diancifa.cc.

WhatsApp: +8615857777578

WhatsApp: +8615857777578