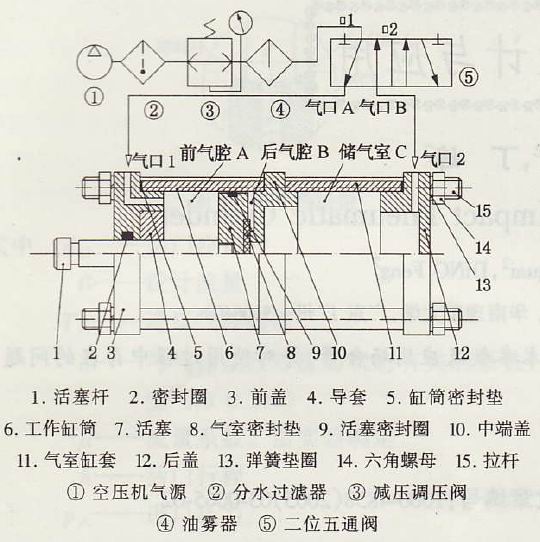

Impact cylinder structural composition diagram

The structure and working principle of the impactcylinder are shown in Figure 1. Its structure More complex than an ordinary cylinder, it is composed of a working cylinder to the left of the middle end cover 10 and an air storage chamber to the right of the middle end cover. The working cylinder is divided into a front air chamber A and a rear air chamber B by the piston 7, and the rear air chamber There is an air storage hole dO located in the center of the middle end cover between B and the air storage chamber C, which is connected or closed. Its state is determined by the relative relationship between the air chamber seal 8 on the rear end of the piston and the middle end cover, that is, the piston and the middle end cover. Relative relationship between mid-end caps. When the piston is close to the middle end cover, the air chamber sealing gasket blocks the air port of dO. At this time, the rear air chamber B and the air storage chamber C are not connected. On the contrary, when the piston leaves the middle end cover, the air chamber sealing gasket also leaves the middle end cover. Open the end cap and immediately open the dO air port. At this time, the rear air chamber B is connected to the air storage chamber C. Because the air storage chamber C, air hole dO, air chamber sealing gasket, etc. are added to the structure, it can be seen from the following working principle analysis that the impact cylinder can produce a large impact force.

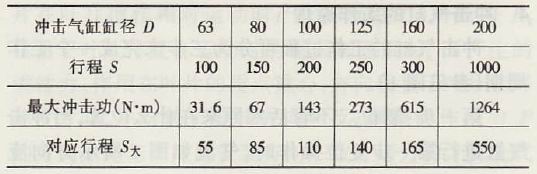

Basic parameters of impact cylinder

1. Bore diameter D range: 63, 80, 125, 160, 200;

2. Stroke range: (1-5)D, where D is the cylinder diameter;

3. Working medium: dry and clean compressed air that removes moisture, dust and oil mist;

4. Working pressure: 0.25-0.8MPa;

5. Pressure resistance: 1.2MPa;

6. Operating temperature range: -5℃~+8O℃ (but under non-freezing conditions);

7. Environmental relative humidity: ≤95%;

8. The relationship between the maximum impact power and the cylinder diameter and stroke is shown in Table 1.

The work of the impact cylinder mainly refers to its instantaneous operation behavior that produces the maximum impact power. Since the impact cylinder itself has the function of generating a large impact energy, it is particularly suitable for occasions that only require instantaneous action, such as printing characters and breaking bamboo and wood. For example, there is a bamboo processing factory in a certain province. It initially used a buffer cylinder, but it failed to achieve the ideal situation of breaking bamboo. Later, it chose an impactcylinder, the purpose of breaking bamboo can be successfully achieved. It can be seen that the special functions of the impact cylinder are increasingly playing an irreplaceable role.

The above isImpact cylinder structure Composition diagram, basic parameters of impact cylinderContent introduction, if you want to know more related information, please log in to Sunway Pneumaticwww.diancifa. ccView.

WhatsApp: +8615857777578

WhatsApp: +8615857777578