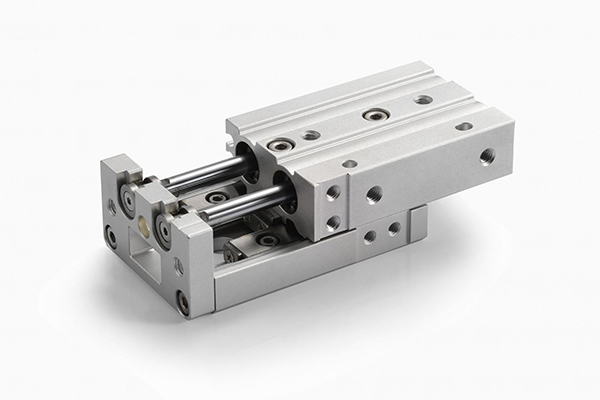

The working principle of the pneumatic slide table: Input compressed air to the cylinder on the fixed mold, guide rod It is pushed by the cylinder at one end and pushed in the opposite direction. The pushing stroke depends on the length of the guide rod.

Characteristics of slide cylinder

1. Compact integration of slide table, cylinder worktable and cylinder;

2. Precision cylinders are suitable for pneumatic slides used in precision assembly;

3. High rigidity/high precision, optional with adjustable stroke device (0-5mm);

4. The slide cylinder adopts cross ball guide rail, which has low friction and can achieve smooth movement without looseness;

5. The combination of cylinder and workbench reduces the overall size;

6. Adopt a double-cylinder structure to obtain twice the output force;

7. Built-in magnetic ring type, magnetic switch can be installed.

8. PneumaticSlide cylinderGenerally used for transportation of precision instruments, the accuracy is relatively high.

Application of slide cylinder

In industrial applications, pneumatic slides not only require good rigidity and repeatability, but their durability, labor-saving characteristics, and load capacity are all parameters that should be paid attention to in design and application. When selecting a slide cylinder, attention should be paid to factors and parameters such as pressure, bore, stroke, working environment, rod end connection method, cylinder fixing method, interface size and location, sealing requirements, buffering requirements, installation space limitations, load, etc. In order to choose the appropriate slide cylinder.

The above isSlide cylinder Characteristics and applicationsContent introduction, want to know moreCylinderFor related information, please log in to Sunway Pneumaticwww.diancifa.cc Check.

WhatsApp: +8615857777578

WhatsApp: +8615857777578