Locked cylinder operating instructions and installation methods Locked cylinder operating instructions and installation methods

1. In the locked state, if pressure is supplied to port A when the ports on both sides are not pressurized, there will be a situation where the lock is not released or the locking protrusionSuddenly lifted, the big danger of the piston rod flying out. When releasing the locking mechanism, be sure to supply pressure to port B and release the locking mechanism without load.

2. If the quick exhaust valve is used to speed up the descent, sometimesCylinderThe body starts to move before the lock pin, and cannot be released normally. Therefore, pleasedo not use quick exhaust valves on locked cylinders.

3. Please do not use three-position solenoid valves: Please do not use them in combination with three-position (especially middle-sealed metal-sealed type) solenoid valves. If there is pressure inside the air port on the side with the locking mechanism, the lock will not work. In addition, sometimes even if it is temporarily locked, air leaking from the solenoid valve will enter the cylinder, and the lock will be released after a period of time.

4. If the locking mechanism side is subject to back pressure, the lock may be released. Therefore, please use a single or integrated individual exhaust type solenoid valve.

5. In the case of a cylinder with adjustable slow motion, if the air slow motion valve needle on the locking mechanism side is over-tightened, the piston will sometimes produce about span>Block, causing damage to the locking mechanism, so the needle valve should be adjusted so that the piston will not be restrained.

6. When the manual operation of the locking mechanism is completed, be sure to reset the manual device to its original position. In addition, please do not perform manual operations outside of adjustment time, otherwise it will be dangerous.

7. Please unlock the cylinder when installing and adjusting it. Installation and other operations in the locked state may sometimes cause damage to the locking part.

8. Please do not use multiple cylinders at the same time: Please never use more than 2 Locked cylinder is used to drive one workpiece at the same time. Sometimes the lock on one of the cylinders cannot be released.

9. Please use the speed control valve under exhaust throttle control: During intake throttle control, sometimes the lock cannot be unlocked.

10. On the locked side, be sure to use the cylinder stroke end: if the cylinder piston does not reach the stroke end, the lock may not work or the lock may not be released.

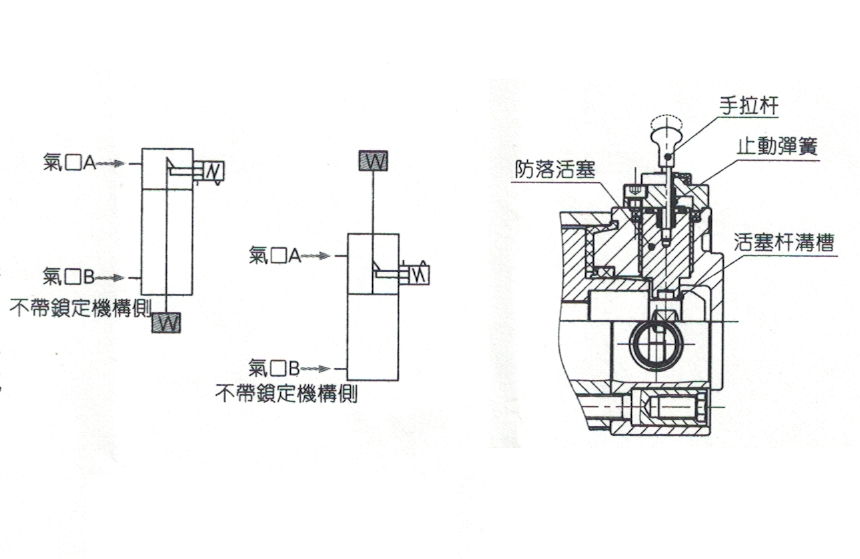

11. Manual non-locking release method: Screw the hand lever into the anti-fall piston, and use a force of more than 20N to pull the bolt out 4mm. After the anti-fall piston moves, unlock. (When installed horizontally without load or when the air port on the opposite side is pressurized) Or, after letting go, the anti-drop piston returns to the original position through the action of the stop spring and enters the piston rod groove, and the piston becomes locked.

The above isInstruction Manual and Installation Method of Locking Cylinder. Instruction Manual and Installation Method of Locking Cylinder Content introduction, if you want to know more information about cylinders, please log in to www.diancifa.cc of Sunway Pneumatics.

WhatsApp: +8615857777578

WhatsApp: +8615857777578