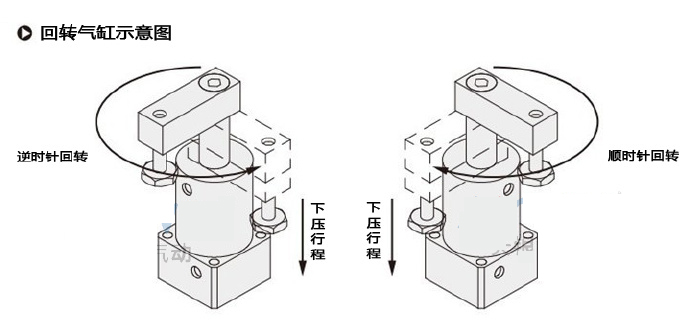

Working principle diagram of rotary clamping cylinder

The rotary cylinder is also called the rotary clamping cylinder. Its working principle isCylinder A groove is opened on the piston rod, and a convex device is installed on the front cover or cylinder to cooperate with the groove. It is driven by air pressure or hydraulic pressure to realize that the piston and piston rod complete rotation first during work, and then rotate to the designed position and angle and then complete the clamping action (press down and clamp the workpiece in a straight line).

When the rotary cylinder is working, the piston rod that moves axially rotates at a certain angle (usually 90 degrees), and other angles can also be customized according to usage requirements. Usually, the piston rod is equipped with a cross arm pressure plate or other specific fixture, which can rotate 90 degrees to clamp the workpiece when moving downward. After the processing is completed, it rises to release the workpiece, and then rotates back to the original position 90 degrees. The main purpose is to avoid the cross arm pressure plate. The workpiece position is convenient for replacement.

Advantages of rotary compression cylinder

1. The rotation gap is more than 50% smaller than ordinary cylinders on the market. It adopts a 3-slot orbital structure and ball design to run more smoothly

2. The hardness of the rotating rod is more than 3 times that of the ordinary cylinder, and it is made of high-carbon steel material with special treatment.

3. The accuracy of cooperation is more than 30% higher than that of peers. All accessories are machined by high-precision machining centers, and all imported seals are used to ensure service life.

The main quality problems of low-priced rotary cylinders currently on the market are:

1. The rotation gap of the rotary cylinder is too large and the rotation is not smooth, causing high-precision equipment and production lines to be unable to accurately position and work normally.

2. The rotary cylinder has a short service life, and the material selection and hardness of the rotary rod are unqualified, resulting in unstable operation. High-precision industrial equipment parts do not tolerate quality failures. Equipment failures are notThe cylinder can compensate for its own value.

The above isRotary clamping Cylinder working principle diagram, advantages of rotary compression cylinderContent introduction, if you want to know more related information, please log in to Sunway Pneumatic View at www.diancifa.cc.

WhatsApp: +8615857777578

WhatsApp: +8615857777578