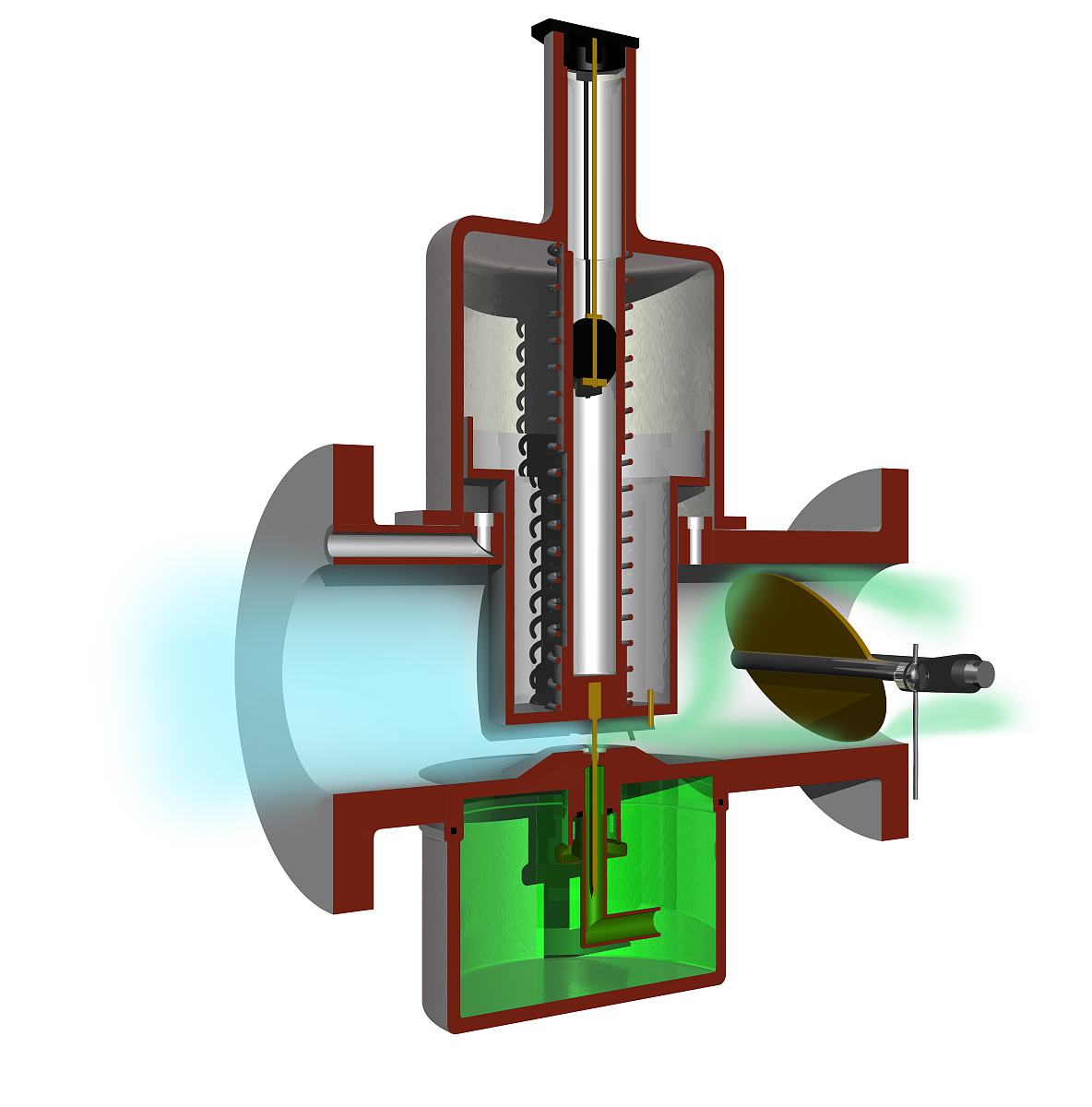

The core component of the balancing cylinder is a large flow, large discharge, and high-precision pneumatic pressure reducing valve. This pressure reducing valve is directly related to the positioning accuracy of heavy objects. , the amount of external force required to move a heavy object, and the speed of moving a heavy object. The inlet pressure of the two pilot pressure reducing valves is taken from the main pipeline and serves as the pilot valves for heavy load balance and no-load balance respectively. The two pilot gases are fed into the two-position three-way reversing valve. The reversing valve is used to switch the heavy load balance. and no-load balance. After passing through the reversing valve, the pilot gas flows into the air-controlled pressure reducing valve, and the outlet pressure of the air-controlled pressure reducing valve is equal to the corresponding pilot pressure. The gas in the main pipeline is decompressed by the pneumatic pressure reducing valve and then flows into the cylinder.The cylinder is filled with gas and the piston rises, thereby pulling up the heavy object.

When the heavy object is in a stationary state after being hoisted, it means that the heavy load balance is reached. At this time, only a small external force is needed to break the balance and the weight can be easily lifted. Lift or lower heavy objects. For example, when pulling down a heavy object to break the balance, when an external force is used to pull down, the piston in the cylinder moves downward. At this time, the pressure in the cylinder rises and exceeds the set pressure (this set pressure is the pressure at equilibrium). The pressure will be discharged from the discharge port of the air-controlled pressure reducing valve. The result of such a process is that the piston (weight) drops to a certain position and becomes stationary, and the pressure in the cylinder returns to the previous equilibrium pressure. On the contrary, the same principle applies when lifting a heavy object upward to break the pressure balance in the cylinder, except that one of the gases flows in the reverse direction (from the cylinder to the exhaust port of the air-controlled pressure reducing valve), and the other flows in the forward direction (the air-controlled pressure reducing valve). valve flows into the cylinder).

The above is the function of the balancing cylinder and the working principle of the balancing cylinder. If you want to knowmore relevant information, please log in to www.diancifa.cc.

WhatsApp: +8615857777578

WhatsApp: +8615857777578