Working Principle of Power Cylinder

There is a piston working in each cylinder. During actual work, the force of each action is not the same. When the piston rod comes out, all the pistons produce push force, but when it returns, only one piston produces pull force. If the workpiece or mold is relatively heavy and requires return pulling force, when the piston rod is pulled back, all pistons can generate pulling force.

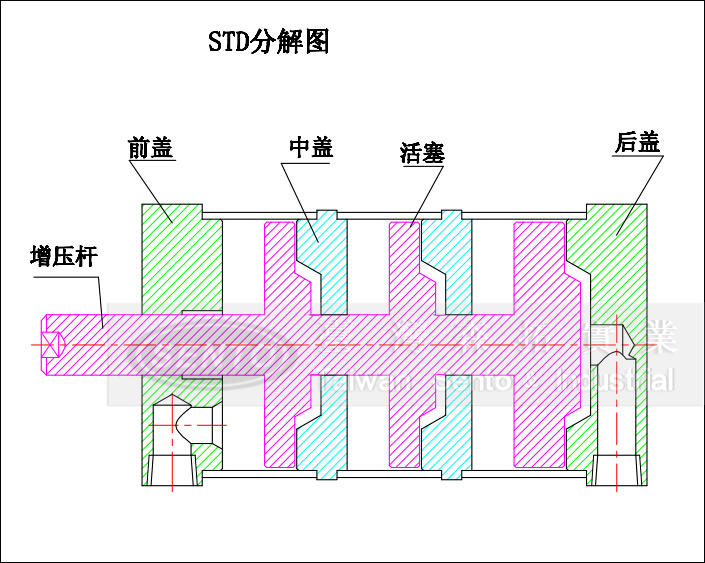

Internal Structure of Power Cylinder

The Power cylinder has the most compact length and size, with multiple layers superimposed and multiple pistons bearing force at the same time, doubling the forceThe output force of the cylinder. A multi-layer force-increasing cylinder has a piston in each layer of the cylinder, but the force received by the piston during the pushing and pulling process is not equal. If thrust work is required, all pistons will generate thrust when the piston rod is pushed out. On return, only one piston exerts pulling force. Power CylinderUsing the same pressure source, the output is several times that of the same cylinder. The output is large. The multi-layer piston is combined and the output is multiplied. It is suitable for oil-free operation with short stroke and high output.

Features of Power Cylinder

Bili cylinder has the characteristics of reliable operation, good durability, low lifting pressure, good sealing, smooth movement, beautiful appearance and strong interchangeability. By mounting on the piston Install a polytetrafluoroethylene support ring to maintain uniform sealing performance when the piston moves, reducing wear and extending service life. The buffer device adopts a new foreign structure, which can function as a one-way valve and make the cylinder structure more compact and reasonable.

WhatsApp: +8615857777578

WhatsApp: +8615857777578