What is a cylinder?

cylinder is an English word, noun. When used as a noun, it means "cylinder;cylinder;cylinder;[number] cylinder;cylindrical object”.

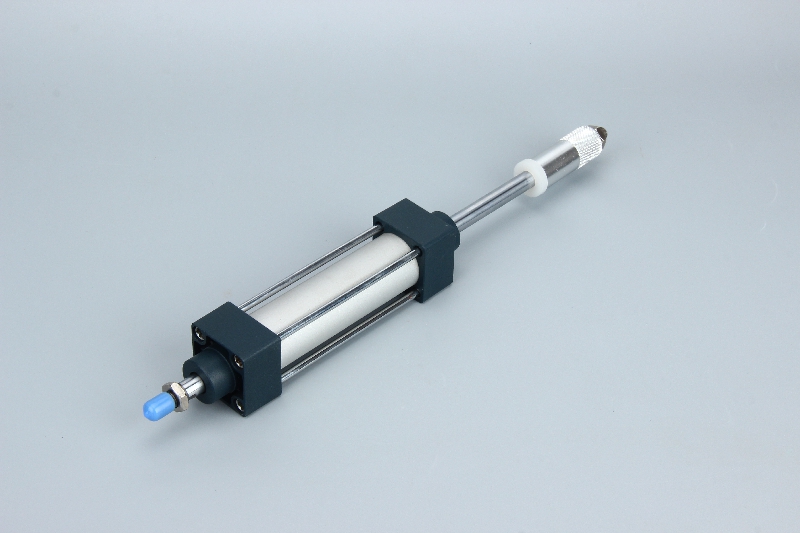

The cylinder is a pneumatic actuator that converts the pressure energy of compressed air into mechanical energy. It is the most common actuator in non-standard automation control. It also cooperates with solenoid valves and magnets. Reed switch. Through the description of the control of this component, I would like to express the basic thoughts on control and discuss with you on understanding. Let me make it clear first that there are many types of cylinders. I will not introduce them in detail here. This article mainly explains the cylinder cylinderThe working principle of the control, and it is a general control. Special usage is not within the scope of this article.

First of all, as for the control of the solenoid valve, whether it is a single solenoid control or a double solenoid control, we will design it according to the double solenoid control. If it is a single solenoid control, we will One of the output points serves as a backup point. When we use a bus-type valve island, there will be such a mandatory reservation when installing the valve plate on the valve island. In addition, it is emphasized that it is best not to arrange solenoid valves at all 8 points of a BYTE. It is best to leave one valve plate empty. When using a combination of valves, try to arrange them in multiples of 4, because 4 solenoid valves are exactly one BYTE.

Let's talk about the reed switch. Since a reed switch is used, the cylinder piston must have a magnetic ring. Children who are new to the industry often forget this. It is recommended that you use a three-wire reed switch and try not to use a two-wire reed switch, mainly for longevity reasons. There is also the issue of signal selection between PNP and NPN. This depends on the type of input point on the controller. Of course, PNP and NPN can be converted through a conversion cable, which increases the cost. Do not apply it this way unless there are special circumstances.

Working principle of cylinder

cylinder cylinderThe control is very simple, but the alarm setting is more complicated. Logically, we usually set the two ends of the cylinder to the original position and the working position respectively. Naturally, there are two alarms, that is, when the cylinder is not in the position it should be within the specified time (there are two delay settings here) s position. Another alarm is that two positions exist at the same time, which is a reset. Generally speaking, these are the three alarms. In fact, there are two alarms. This depends on the actual movement of the cylinder. Whencylinder cylinderWhen it moves to the desired position, there is another process that it first leaves the current position. These two alarms are that the cylinder is within the specified time (there are two alarms here). delay setting) to leave your current location. When the cylinder reaches the desired position, it must be delayed for a period of time before proceeding to the next action. This delay is basically measured in milliseconds.

To summarize, usually acylinder cylinderThere are two input points, two output points, two in-position delay settings, four alarm delay settings, and five alarm messages. You can write standard function blocks for cylinder control based on this information. In addition, a reminder to consider cylinder< /strong>To monitor and trace motion, add the cylinder cylinderRecording the number of movements and recording the cylinder action time, so as to provide the necessary maintenance data for the intelligent system to produce maintenance reports.

WhatsApp: +8615857777578

WhatsApp: +8615857777578