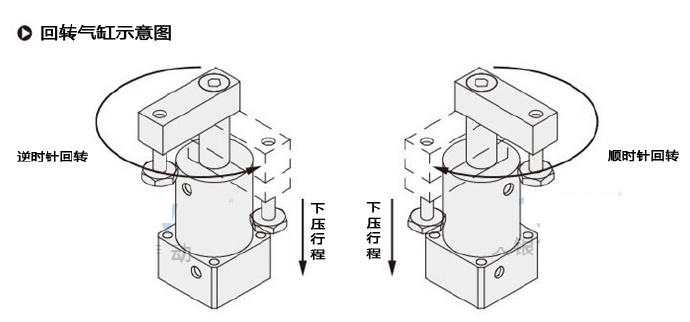

When the rotary cylinder is working, the piston rod that moves axially rotates at a certain angle (usually 90 degrees), and other angles can also be customized according to usage requirements. Usually, the piston rod is equipped with a cross arm pressure plate or other specific fixture, which can rotate 90 degrees to clamp the workpiece when moving downward. After the processing is completed, it rises to release the workpiece, and then rotates back to the original position 90 degrees. The main purpose is to avoid the cross arm pressure plate. The workpiece position is convenient for replacement.

Rotary cylinders are widely used in the current automated production lines and fixture clamping industries, especially in the electronic manufacturing and CNC tooling and fixture industries in coastal areas. Rotary cylinders The wear resistance of the rotating rod is more than 2 times higher than that of its peers.

According to the working principle and working requirements of the rotary cylinder, the parameters and models of the rotary cylinder are classified as follows:

Rotation angle: 90 degrees, 180 degrees, 360 degrees

Rotation direction: left turn and right turn are available,

Rotary cylinder bore: 20, 25, 32, 40, 50, 63

Installation method: through-hole installation, flange can be installed on the rod-less side, and a cross arm can be installed on the rod end.

Rotary stroke: There is a certain rotation stroke, and the stroke also changes with different cylinder diameters.

Press clamping stroke: 5, 10, 15 kinds to choose from.

Note: The rotary stroke and clamping stroke are accumulated to form the total stroke of the rotary cylinder.

Rotary cylinder pressing diagram

Rotary cylinder working rising chart

360-degree cycle 180-degree rotation clamping cylinder, which rotates 90 degrees or 180 degrees, and returns to the origin after 4/2 rotations. It is divided into clamping stroke and There are two types without clamping stroke.

The cyclic 360-degree rotating cylinder can rotate 90 degrees or 180 degrees each time, and return to the original position after a total of 360 degrees of rotation.

Advantages of 180-degree rotary clamping cylinder:

1. This cylinder makes up for the inability of ordinary rotary cylinders or swing cylinders to achieve cyclic rotation and intermediate positioning functions, and has the function of rising or falling.

2. Ordinary corner cylinders only have the functions of rising and turning. They need to return according to the original trajectory before descending. However, this rotating pressure cylinderCylinder realizes rising-rotating-descending The descending function can be realized without returning to the original trajectory, and it can loop 360 degrees infinitely.

3. 180 degreesRotary clamping cylinder Combined with the mechanical arm, it can realize the integrated grabbing-moving-release! It solves the functions that require the combination of multiple cylinders in the automation equipment industry and saves space.

WhatsApp: +8615857777578

WhatsApp: +8615857777578