What is an oscillating cylinder?

is a pneumatic actuator that uses compressed air to drive the output shaft to perform reciprocating rotation within a certain angle range. Used for turning, turning, sorting, clamping objects, opening and closing valves, and arm movements, etc.

Commonly usedSwing cylinderModels include: MSQB, MK, CRB2, MSZA, ACK, CRQ2, CRA1, etc.

Commonly used bore ranges are: 10, 12, 15, 20, 25, 30, 32, 40, 50, 63, 70, 80, 100, 200mm.

Working principle of swing cylinder

Since the cross-sectional area of the plunger chamber is very small, the swing cylinder consumes very little air when moving rapidly and will not affect the pressure of the air source. In the slow working stage, compressed air flows into the rodless cavity of the swing cylinder and the inner cavity of the plunger cylinder at the same time, causing the piston rod to generate thrust.

InSwing cylinderWhen the inner diameter is large and the idle stroke is relatively long, the swing cylinder has a good energy-saving effect. A wear-resistant block is connected to the boss of the buffer rod through bolts. A small piston rod is also installed in the swing cylinder base. A compression spring and an adjustment block are set on the small piston rod. In the swing cylinder base, there is a The inner cavity that accommodates the buffer rod is connected to the air inlet duct that is connected to the inner cavity of the swing cylinder, and the air passage that can connect the inner cavity that accommodates the buffer rod to the front and rear chambers of the small piston rod are respectively connected.

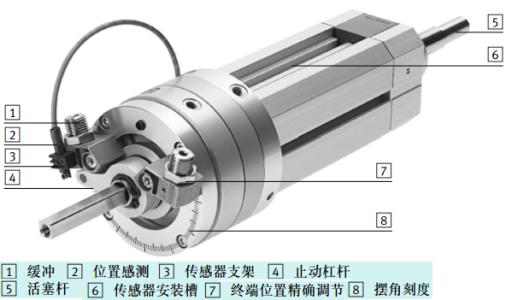

Internal structure of swing cylinder

Swing cylinder includes lock nut, guide sleeve, rear cylinder head, intake plunger, cylinder block, sealing ring, piston, front cylinder head, swing cylinder with plunger Piston rod, etc., there is a sealing ring between the piston of the swing cylinder and the inner wall of the cylinder. There is a piston rod with a plunger swing cylinder on the piston. The outer wall of the piston rod of the plunger swing cylinder is connected to the front cylinder head through a guide sleeve. Connection, the rear cylinder head is provided with an air intake plunger that matches the piston rod of the plunger swing cylinder.

Features of swing cylinder

The swing cylinder has the advantage that when the air supply pressure of an ordinary cylinder gradually decreases or the air is stopped, the piston rod of the swing cylinder will not slide downward. It can greatly Improve the working reliability of ordinary swing cylinders;in addition, it has the advantages of simple structure, convenient use, reasonable layout, safety and reliability.

Swing cylinder application instructions

The swing cylinder can be combined with other cylinders for application. Example: A certain mechanism has two telescopic cylinders, which are installed on two symmetrical planes of the rotation axis. The rotation axis and the swing cylinder The cylinders are connected so that the swing of the swing cylinder drives the two telescopic cylinders to swing back and forth in an angle range of 180° through the rotating shaft.

The ends of the piston rods of the two telescopic cylinders can be connected to suction cups, air claws and other components to complete the telescopic cylinder extension (suction cup material collection), telescopic cylinder contraction, swing cylinder flipping, Telescopic cylinder contraction (suction cup feeding) assembly and other actions, and the two telescopic cylinders can perform material picking and feeding actions at the same time, greatly improving work efficiency.

For automatic assembly, high positioning accuracy is required. In addition to the installation dimensions of the two telescopic cylinders and the installation dimensions of the suction cup, which require a high degree of symmetry relative to the center of rotation, another The important factor is that the swing angle of the rotary cylinder strictly reaches 180°. Because the picking and feeding installation positions of automated assembly equipment are fixed. Only in this way, two telescopiccylinderOnly after 180° flipping can the material be picked up and fed accurately at a fixed point. This is also the assembly and debugging idea of the equipment.

WhatsApp: +8615857777578

WhatsApp: +8615857777578