1. Cylinder selection steps:

a: Select the cylinder type according to the operation mode: rotary cylinder, three-axis cylinder, pneumatic finger, etc. or other types of special cylinders;

According to the power source or usage requirements, confirm that the cylinder operation modes include double-action, single-action spring press-in and single-action spring press-out.

b: Select cylinder installation type. Different series have different installation methods, mainly including basic type, foot type, flange type, U-shaped hook, and shaft lug type.

C: When calculating the cylinder force, determine the cylinder diameter (general theoretical output force selection information is provided)

d: Selected cylinder stroke: It depends on the occasion of use and the stroke of the mechanism, but generally the full stroke is not selected to prevent the piston and cylinder head from colliding. If it is used in a clamping mechanism, etc., a margin of 10 to 20 mm should be added based on the calculated stroke.

e: Selected buffer: no buffer, rubber buffer, air buffer, hydraulic shock absorber

F: Selected magnetic switch: mainly used for position detection, requiring a built-in magnetic ring in the cylinder

g: Selected cylinder accessories: including related connectors.

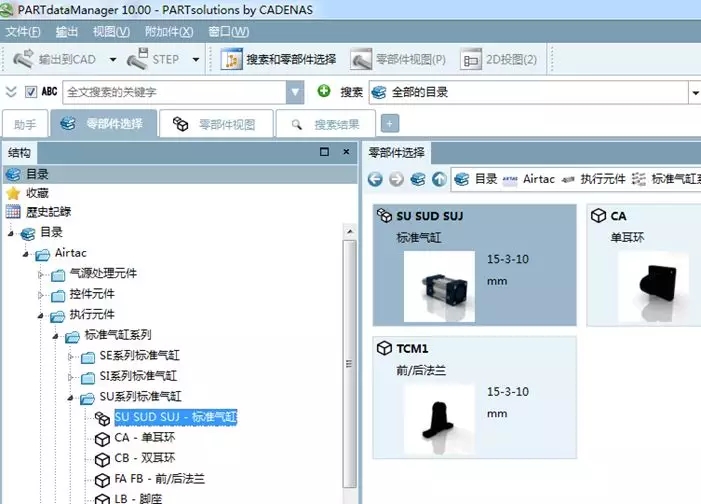

2. YATACO software selection method:

①Click on the Chinese Taiwan version

②Enter the program and click on the directory in sequence

[AirTAC cylinder and the like are actuators, valves and the like are control components, accessories are auxiliary components, and the rest are air source processing components]< /span>

③Click to open the actuator list and select the required type of cylinder

④SelectCylinderSpecification parameters: such as cylinder diameter, stroke, installation method, joint specifications, sensor switch, etc.

⑤Click output to save the format

WhatsApp: +8615857777578

WhatsApp: +8615857777578