What is a double cylinder?

Double-linked cylinder Double-linked cylinder is also known as double-rod cylinder, double-piston cylinder, etc. It has high non-rotation accuracy and 2 times the output force, and has strong resistance to side loads. It adopts rolling bearings and ball bearings and does not require oiling.

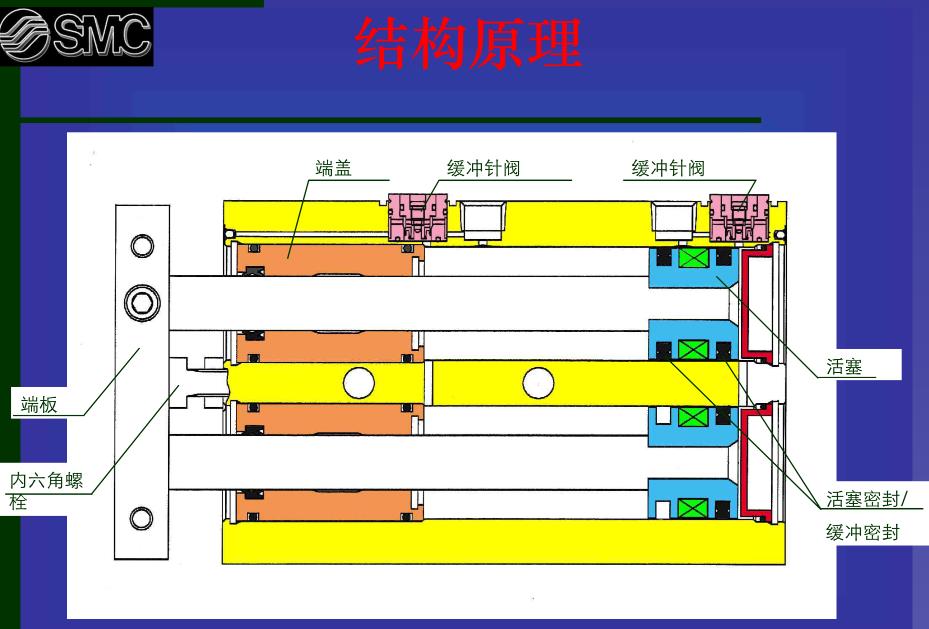

Double cylinderThe end cover is equipped with intake and exhaust ports, and some also have a buffer mechanism in the end cover. The rod side end cover is equipped with a sealing ring and a dust ring to prevent air leakage from the piston rod and external dust from mixing into the cylinder. The wear-resistant ring length uses materials such as polyurethane, polytetrafluoroethylene, cloth-filled synthetic resin, etc. The width of the piston is determined by the size of the sealing ring and the necessary length of the sliding section. The sliding part is too short, which can easily cause early wear and jamming.

The function of double cylinder

Twin cylinders have high non-rotation accuracy and small piston rod end windings, making them suitable for precise guidance situations. There are two sets of inlet and exhaust ports at both ends of the cylinder for actual needs;There are mounting holes on all sides of the body except the axial direction, providing customers with a variety of installation and fixing methods;most importantly, the double cylinder is copper-free and can be used in the lithium battery industry.

Double cylinder internal structure

Double cylinderInstallation and usage precautions

Before connecting the piping, fully purge the piping and joints with clean air.

The mounting surface of the workpiece must be flat with a parallelism of less than 0.05mm.

The sliding surface of the piston rod must not be damaged to avoid damage to the seal, resulting in air leakage and malfunction of the cylinder.

When installing the cylinder, the two piston rods should not be twisted. Otherwise, the surge in cylinder action resistance will cause accelerated wear of the guide bearing, reduce the guide accuracy, and cause air leakage.

When the cylinder moves, do not get your fingers caught between the cylinder body and the end plate. When installed, the piston rod should be in a retracted state.

WhatsApp: +8615857777578

WhatsApp: +8615857777578