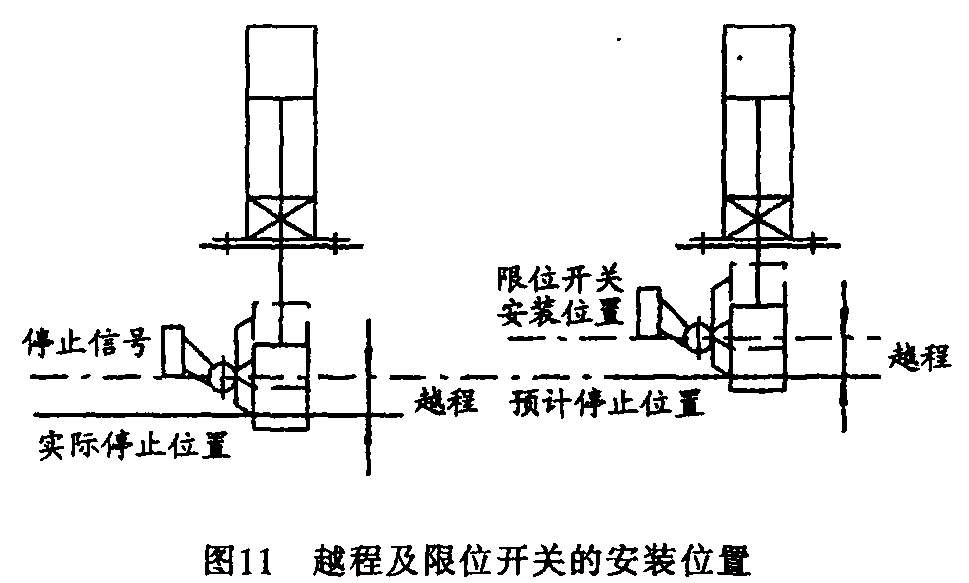

Due to mechanical locking, thiscylinder is relative to the There is a delay in the stop signal, and the cylinder stroke affected by this time delay is called "overtravel". The distance between the maximum overtravel and the minimum overtravel is the stopping accuracy. This relationship diagram is shown in Figure 11. Before setting the limit switch to overshoot the expected stop position, the limit switch should have a detection length (stop) such as overtravel. Usually the limit switch operates within the range of 8 to 14 mm. When the overtravel exceeds this range, the contact should still remain on the switch load side.

(1) In order to obtain higher stopping accuracy, it is recommended to use air pressure locking or spring and air pressure combined locking to reduce the time between sending a message and stopping. Choose a fast, responsive, and DC controlled solenoid valve.

(2) Due to factors such as damping on the inner wall of the piping, lock release delays often occur. For this reason, the piping distance between the solenoid valve and the cylinder is shortened as much as possible, especially the solenoid valve that controls the lock release is assembled as directly as possible on the air inlet of the cylinder locking device.

(3) Load fluctuations during the two-way stroke of the cylinder will cause changes in piston speed, making the cylinder stop position range wider. Therefore, it is necessary to install and adjust it correctly to avoid load fluctuations during the two-way stroke of the cylinder, especially before stopping.

(4) During the buffering process, the piston movement speed changes greatly, and the stop position also changes during starting and subsequent stopping. Therefore, in the case of short-stroke movements, the specified accuracy is sometimes not achieved during starting and subsequent stopping, and this needs to be considered when selecting.

(5) When installing the pneumatic system, the pipeline must be thoroughly flushed and blown out. Dust, metal and fiber fines must not enterCylinder and solenoid valve, when used in dusty environment, should be equipped with protective covers.

WhatsApp: +8615857777578

WhatsApp: +8615857777578