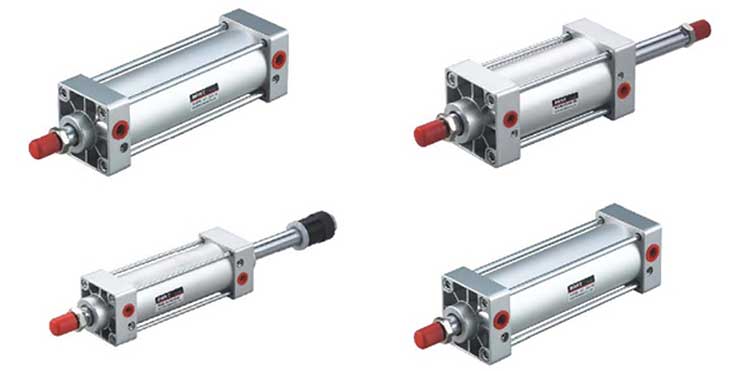

SC standard cylinders are suitable for use in various industries and are specially used in dust removal devices. This kind of cylinder is usually equipped with a lift valve and an electromagnetic pulse valve for use together. Generally speaking, manufacturers can design and produce different bore sizes and cylinders with different strokes, cylinder flanges, single ears and double ears of cylinder configuration components, as well as cylinder standard rods and cylinder extensions according to customers' specific requirements and actual needs. Air rods etc.

Structural features

1. The end cover of SC standard cylinder uses new pressure casting processing technology.

2. The cylinder barrel is made of finely drawn aluminum alloy pipes with higher quality, and the internal surface is made by hard anodizing.

3. The surface of the cylinder's piston rod uses pre-rolling hardening processing technology. Through hard chromium plating and fine grinding, it has excellent rust prevention and wear resistance.

4. The sealing parts on the SC standard cylinder have a novel structure and excellent quality. They can operate without abnormality even when lubricating oil is not provided. The pressure is small when the cylinder is initially started, extending its service life.

5. Both the front and rear end caps of the cylinder are equipped with spare ventilation screws to facilitate the user to choose the installation location.

Installation and use

1. If the load changes during work, a cylinder with sufficient output power should be selected. Under high temperature conditions, a corresponding high-temperature resistant cylinder should be selected.

2. Before piping the cylinder, debris in the pipe must be removed to prevent debris from entering the cylinder.

3. The medium used in the cylinder should be filtered by a filter element of 40μm or above before use.

4. In low-temperature environments, anti-freeze measures should be taken to prevent moisture in the system from freezing.

5. The cylinder should undergo no-load test operation before use. Before operation, the buffer should be adjusted to the minimum and gradually increased to avoid excessive impact and loss of the cylinder.

4. The cylinder should avoid side loads as much as possible during operation to maintain the normal working life of the cylinder.

5. If the cylinder is removed and not used for a long time, attention should be paid to surface rust prevention, and dust-proof blocking caps should be added to the intake and exhaust ports.

WhatsApp: +8615857777578

WhatsApp: +8615857777578